The natural potato chips production line is automatic and complete, including packaging machines

🏭 Natural Potato Chips Production Plant Project – A Golden Business Opportunity

Today, we present one of the most successful and in-demand production projects in both the global and local markets:

> Natural Potato Chips Production Plant (French Fries & Potato Chips)

📈 Why this project?

The food industry is one of the most attractive sectors for investors, due to its consistently high demand, ease of product distribution, and the high daily consumption of its products in cities and villages alike.

Despite the presence of major companies in the market, there is still a significant gap in meeting the growing demand for natural potato products, making this project one of the most profitable and widespread ventures.

🎯 Project Objectives:

To produce high-quality natural potato chips and French fries.

To meet the demand in the local and regional markets.

To provide a product that complies with all health and nutritional standards.

To establish a competitive and widely recognized brand across multiple markets.

To reach a large number of customers through smart and effective distribution.

⚙️ Operational Process:

The project relies on a fully automated production line that operates according to the latest European standards. It consists of several stages, including:

1. Washing and peeling

2. Sorting and cutting

3. Starch removal and blanching

4. Drying and preparation for frying

5. Initial frying (partially cooked)

6. Cooling and heat shock treatment

7. Automated packaging

Each stage utilizes advanced technologies to ensure a high-quality final product.

💡 Project Advantages:

✅ High and consistent demand for the product

✅ Potential for rapid geographical expansion

✅ Ability to produce different types and sizes

✅ Short production cycle and fast capital turnover

✅ Full automation to minimize labor costs

📦 Why a Potato Chips Business?

A staple consumer product found in every household.

High profit margins.

Scalable, adaptable, and suitable for export.

A very large target audience encompassing all age groups.

📢 Message to Investors:

> Before starting, thoroughly study the project from all angles, even if it requires an initial investment in feasibility studies.

Projects based on sound data and meticulous planning have a much higher chance of success.

📌 Marketing Tip:

Focus on building a compelling brand.

Use attractive, modern packaging.

Don't neglect social media marketing.

Target schools, stores, and restaurants as your initial market.

The line consists of the following parts

1_The server is the collection tank 2_ Two-stage potato washing machine 3_Conveyor line with the collection basin 4_Potato peeling machine number 2 5_Conveyor belt for potato inspection 6_Conveyor itinerary 7_ Potato sorting shaker 8_Slicer server 9_potato cutting machine 10_Did he withdraw the starch from the planer? 11_ A bottle for drying water and spreading potato slices 12_ Air drying tunnel 13_Continuous frying 14_Oil drying bottle 15_The examination itinerary 16_The god of flavoring and spice 17_Mutabbal flavor cylinder 18_Itinerary for transporting the packaging machinery server 19_Packing and wrapping machines, number 3

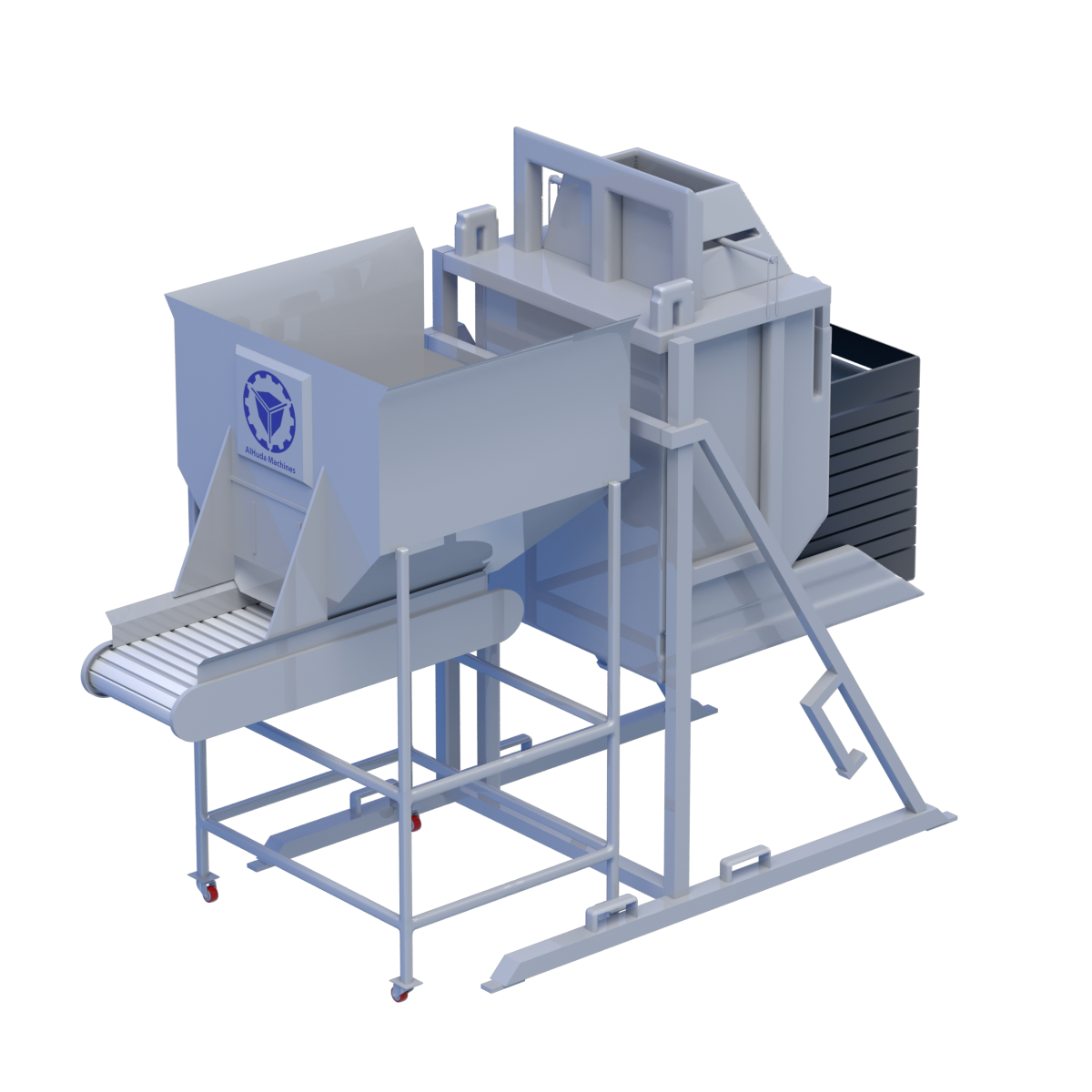

Collector Tank Server with Conveyor Belt

🔹 Advanced Design for Efficiency and Safety. The integrated conveyor tank feeder is essential equipment in production lines, contributing to the efficient transfer and distribution of materials while ensuring precise movement control and safe lifting. Advanced Operation Mechanism:

1️⃣ Powerful and Safe Hydraulic System. The moving part of the feeder is raised and lowered by four hydraulic pistons, ensuring precise control and smooth, vibration-free movement. It relies on an integrated hydraulic pressure system to ensure safe and stable operation.

2️⃣ Durable design to international standards, made entirely of 304 food-grade stainless steel to ensure corrosion resistance and easy cleaning. A robust structure withstands harsh operating conditions, with a compact design that provides an organized and efficient workspace.

3️⃣ High Operational Efficiency: Equipped with a powerful 380/220V | 50Hz | 3.75kW motor to ensure consistent performance. It provides smooth operation thanks to the use of high-quality components that meet industrial production requirements.

4️⃣ Practical Ergonomic Design

✅ Ideal dimensions for easy installation and integration into production lines:

Length: 180 cm

Width: 120 cm

Height: 170 cm

✅ Machine Number: 001

✅ Model: ALEUDA-2025AS-N

✅ Country of Origin: Turkey

✔️ Safe and precise lifting and lowering thanks to the advanced hydraulic system.

✔️ Durable design resistant to harsh industrial conditions.

✔️ Made entirely of 304 stainless steel to ensure the highest standards of hygiene and quality.

✔️ High operational efficiency with a powerful motor and low energy consumption.

✔️ Easy maintenance and cleaning to ensure continuous production.

💡 The ideal solution to ensure smooth and efficient production flow!

Potato Washing Machine

The first step in ensuring the cleanliness and quality of potatoes is the potato washing machine. This machine serves as the first line of defense in the potato processing operation, effectively removing dirt and debris from the potatoes to guarantee their cleanliness before they enter the peeling and processing stages. It utilizes a sophisticated washing system with a variable-speed rotating drum, where the potatoes are gently agitated and washed with clean water to ensure thorough cleaning.

⚙️ Advanced Operating Mechanism:

1️⃣ Innovative Design for Efficient Washing

✔️ Highly efficient removal of dirt and debris from the potatoes.

✔️ Variable-speed drum ensures comprehensive and uniform cleaning.

✔️ Gentle agitation of the potatoes in clean water guarantees optimal washing results.

2️⃣ Robust and Durable Construction

✔️ Made entirely of food-grade 304 stainless steel for corrosion resistance and hygiene.

✔️ Front and rear wall thickness: 12 mm for strength and durability.

✔️ Side wall thickness: 5 mm for enhanced structural integrity and stability.

✔️ 10×10 cm stainless steel 304 profile frame for structural support.

✔️ Outer casing thickness: 3 mm for machine protection and extended lifespan.

3️⃣ Powerful Performance with High-Efficiency Motors

✔️ Electrical power: 5.25 kW – 380/220 V – 50 Hz.

✔️ Advanced electrical system ensures smooth and continuous operation.

✔️ Powerful motors support consistent performance and high operational efficiency.

4️⃣ Practical and Easy-to-Maintain Design

✔️ Easy maintenance and cleaning for continuous, high-efficiency operation. ✔️ A design that ensures smooth and efficient transfer of potatoes to the next processing stage.

✔️ An integrated operating system that minimizes water and energy consumption.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel for hygiene and quality assurance.

✅ Dimensions:

✔️ Length: 600 cm

✔️ Width: 130 cm

✔️ Height: 450 cm

✅ Machine Number: 002

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

✔️ Effective removal of dirt and debris using a variable-speed rotating brush.

✔️ High-quality food-grade 304 stainless steel construction for durability and hygiene.

✔️ Powerful motors for reliable and efficient operation.

✔️ Practical and easy-to-maintain design for extended machine lifespan.

✔️ Optimized water and energy consumption while achieving superior cleaning results.

💡 The ideal solution for ensuring the cleanliness and quality of potatoes before processing!

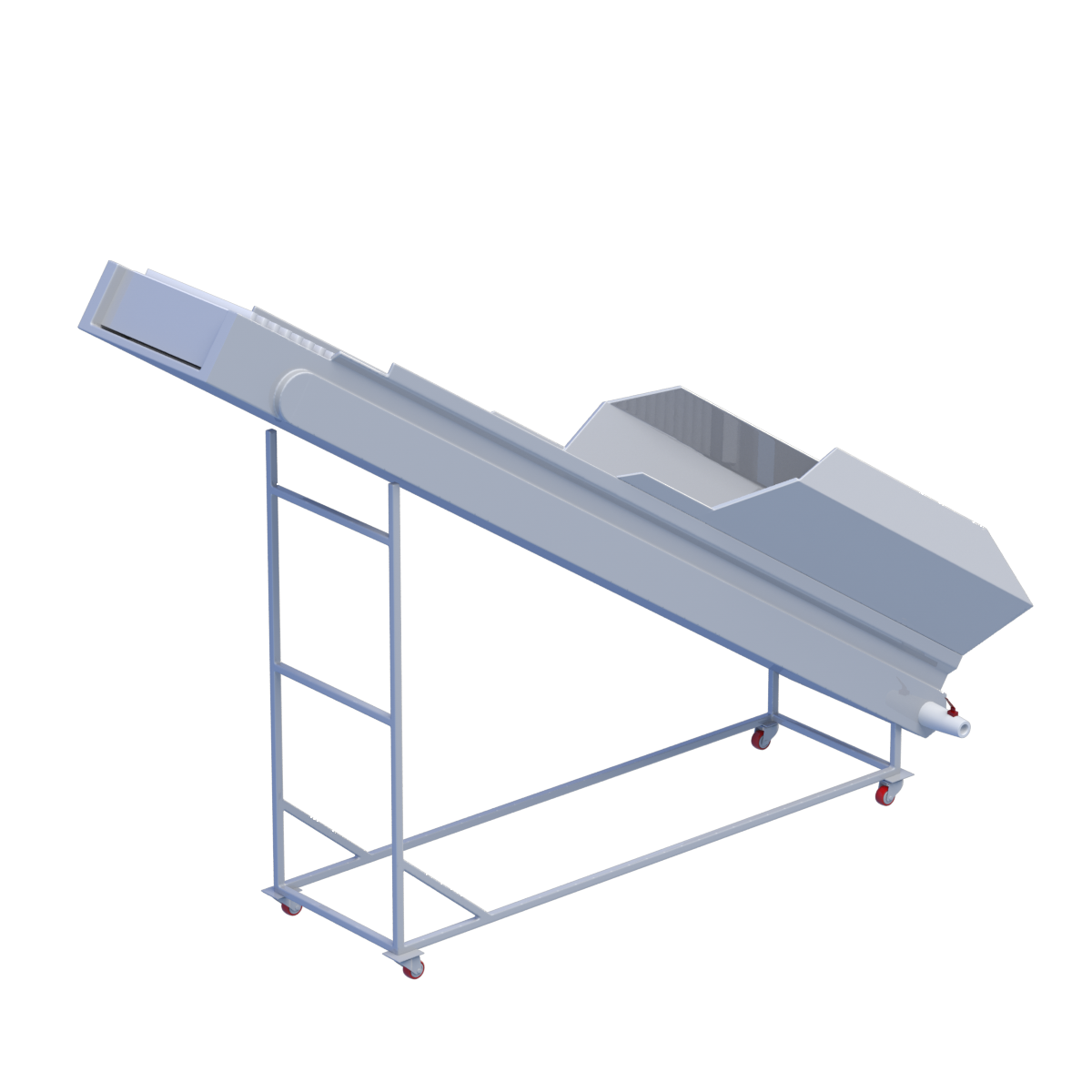

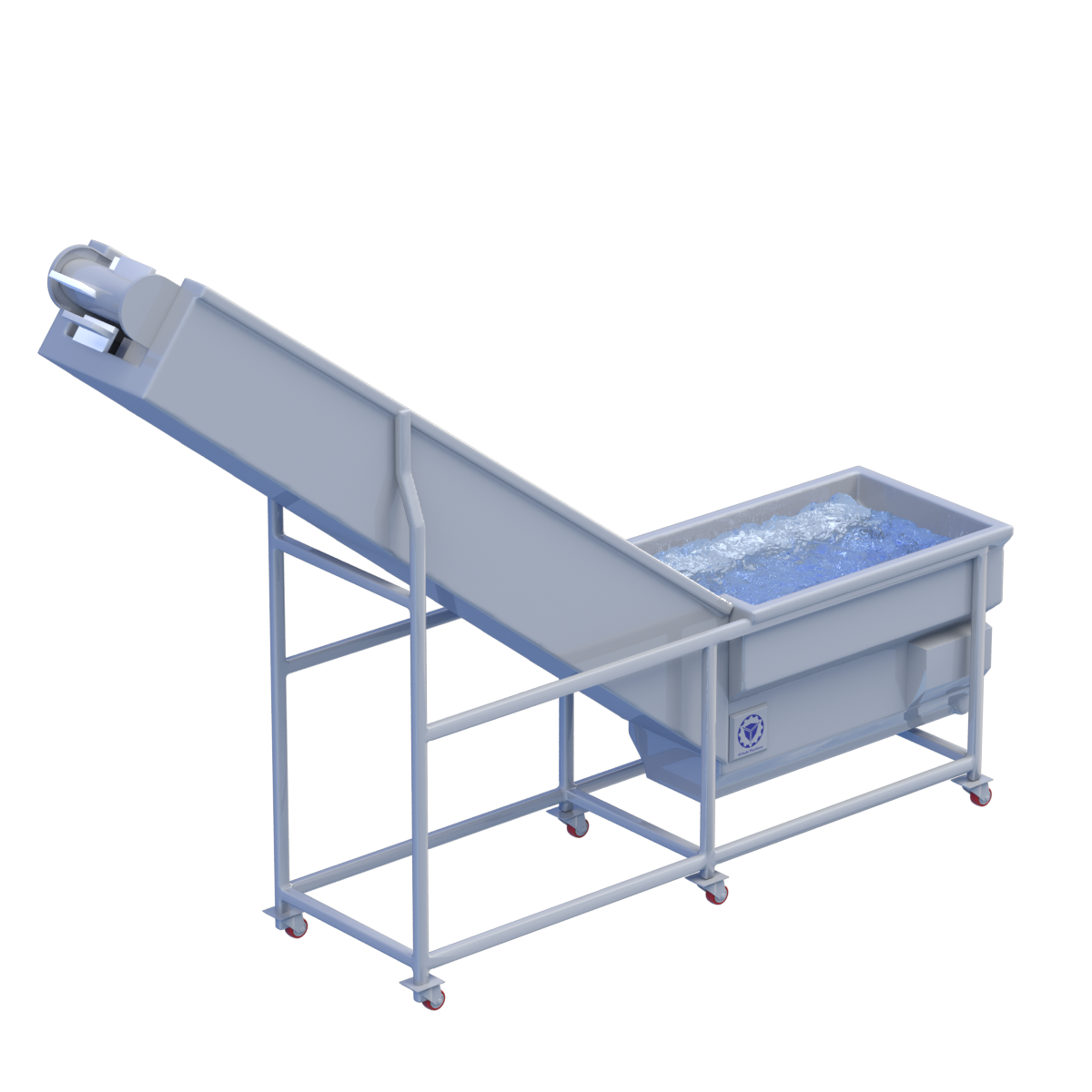

Conveyor with collection basin

A key step in potato washing and ensuring continuous production. The conveyor line, along with the collection basin, washes potatoes with water to remove any remaining dirt before they enter the peeling stage. This ensures the cleanliness of the potatoes and ensures uninterrupted production. The basin features a built-in conveyor belt to transport the potatoes directly to the peeler, ensuring smooth operation and high production efficiency.

⚙️ Advanced Operation Mechanism:

1️⃣ Effective Washing and Continuous Potato Supply

✔️ Removes any dirt stuck to the potatoes to ensure cleanliness before peeling.

✔️ Built-in conveyor belt ensures a continuous flow of potatoes to the peeler without interruption.

✔️ The design ensures no interruption in operation, increasing production efficiency.

2️⃣ Strong and Durable Structure

✔️ Made entirely of food-grade 304 stainless steel for corrosion resistance and hygiene.

✔️ 5 mm wall thickness to reinforce the structure and ensure durability.

✔️ 8x8 cm 304 stainless steel profile frame supports operational efficiency.

3️⃣ High performance with powerful motors

✔️ Electrical power: 3.75 kW – 380/220 V – 50 Hz.

✔️ Advanced electrical system ensures stable and continuous operation.

✔️ Powerful motors support high operational efficiency and reduce energy consumption.

4️⃣ Practical and easy-to-maintain ergonomic design

✔️ Easy maintenance and cleaning to ensure continued operation at the highest efficiency.

✔️ The design allows for smooth transfer of potatoes from washing to peeling without any complications.

✔️ Precise potato flow control to ensure smooth and continuous operation.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to maintain hygiene and quality.

✅ Dimensions:

✔️ Length: 430 cm

✔️ Width: 150 cm

✔️ Height: 360 cm

✅ Machine Number: 003

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

✔️ Effective removal of stuck-on dirt to ensure potato cleanliness before peeling.

✔️ Built-in conveyor belt ensures continuous operation without interruptions.

✔️ High-quality 304 food-grade stainless steel construction ensures durability and hygiene.

✔️ Powerful motors ensure stable operation and high efficiency.

✔️ Practical and easy-to-maintain design to extend the machine's lifespan.

💡 The perfect solution to ensure potato cleanliness and continuous production with high efficiency!

Potato Peeling Machine 2

A key stage for efficient pre-processing potato peeling. The potato peeling machine effectively peels potatoes before they enter the other processing stages. It features a highly advanced peeling system that removes peels with minimal waste, helping to preserve the largest possible quantity of potatoes. The speed of the process can also be controlled using the latest speed variators to ensure maximum efficiency. The machine is designed for easy maintenance, including cleaning and washing, ensuring optimal operation.

⚙️ Advanced Operation Mechanism:

1️⃣ Efficient and Precise Peeling

✔️ Precise peeling removal with minimal waste to ensure maximum utilization of potato grains.

✔️ Advanced peeling system peels potatoes quickly and efficiently.

✔️ Speed control using modern speed variators to ensure optimal adjustment according to production needs.

2️⃣ Strong and Durable Structure

✔️ Made entirely of food-grade 304 stainless steel for corrosion resistance and hygiene.

✔️ Front and back wall thickness: 12 mm to ensure durability and strength.

✔️ Wall side thickness: 5 mm to support the frame and ensure machine stability.

✔️ 10 x 10 cm 304 stainless steel profile frame to support operation.

3️⃣ High performance with powerful motors

✔️ Electrical power: 9.75 kW – 380/220 V – 50 Hz.

✔️ Advanced electrical system ensures stable and continuous operation.

✔️ Powerful motors support high performance and reduce energy consumption.

4️⃣ Practical and easy-to-maintain ergonomic design

✔️ The design allows for easy maintenance and cleaning to ensure continuous operation at the highest efficiency.

✔️ The machine can be easily cleaned to prevent impurities from accumulating and maintain its efficiency.

✔️ Speed control is possible according to production needs to ensure optimal results.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to ensure hygiene and quality.

✅ Dimensions:

✔️ Length: 600 cm

✔️ Width: 130 cm

✔️ Height: 340 cm

✅ Machine Number: 004

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

✔️ Efficient peeling with minimal waste while preserving the maximum amount of potatoes.

✔️ Precise speed control using modern speed variators.

✔️ High-quality 304 food-grade stainless steel construction materials to ensure durability and hygiene.

✔️ Powerful motors to ensure stable operation and high efficiency.

✔️ Practical and easy-to-maintain design to extend the machine's lifespan.

💡 The perfect solution for peeling potatoes efficiently and with high quality before entering the processing stages!

Conveyor belt for checking potatoes before cutting

🚀 A key step in potato inspection and quality assurance before cutting. The potato inspection conveyor belt rotates the potatoes to identify unsuitable ones. The advanced system directs unsuitable ones to designated outlets for isolation in a tank beneath the conveyor belt, helping to maintain the high quality of the potatoes entering the subsequent cutting process. The machine is equipped with a high-performance motor to ensure continuous and efficient movement throughout the inspection process.

⚙️ Advanced Operation Mechanism:

1️⃣ Accurate Inspection and Removal of Unsuitable Potatoes

✔️ The conveyor belt rotates the potatoes to ensure their quality and isolate unsuitable ones.

✔️ Dedicated isolation outlets collect unsuitable potatoes in a tank beneath the conveyor belt to ensure complete filtration.

✔️ The system efficiently inspects the potatoes to prevent unsuitable ones from entering the cutting stage.

2️⃣ Strong and Durable Structure

✔️ Made entirely of food-grade 304 stainless steel to ensure corrosion resistance and high hygiene.

✔️ The frame is 10 x 10 cm thick and made of 304 stainless steel for durable operation.

✔️ Wheel width: 90 cm to ensure stable conveyor belts and smooth potato flow.

3️⃣ High-performance motor

✔️ Electrical power: 2.25 kW – 380/220 V – 50 Hz.

✔️ A powerful motor supports stable operation and ensures smooth potato flow to the next stages of processing.

✔️ Advanced electrical design to ensure long-lasting operation and high efficiency.

4️⃣ Practical and easy-to-maintain design

✔️ Easy maintenance and cleaning to ensure continuous operation at the highest efficiency.

✔️ The design allows for easy collection and effective isolation of unsuitable potatoes.

✔️ Precise workflow control to ensure high performance and operational efficiency.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to maintain hygiene and quality.

✅ Dimensions:

✔️ Length: 400 cm

✔️ Width: 130 cm

✔️ Height: 190 cm

✅ Machine Number: 005

✅ Model: THV-2024PV-B

✅ Country of Origin: Turkey

✔️ Thorough grain inspection to ensure only good quality potatoes are fed into the cutting process.

✔️ Effective isolation outlets to maintain production quality.

✔️ High-quality 304 food-grade stainless steel materials to ensure durability and hygiene.

✔️ Powerful motor to ensure continuous operation and high efficiency.

✔️ Practical and easy-to-maintain design to extend the machine's lifespan.

💡 The perfect solution to ensure potato inspection and removal of unsuitable potatoes before cutting!

Potato Grain Conveyor to Slicer

A key step in efficiently and smoothly transporting potatoes to the slicing machine. The conveyor lifts and transports potatoes to the slicing machine with a built-in water basin, facilitating the initial washing process and reducing friction during transportation. The robust structure, made of 304 food-grade stainless steel, ensures continuous operation and high durability, making it ideal for industrial potato production lines.

⚙️ Advanced Operation Mechanism:

1️⃣ Smooth Potato Transport and Quality Protection

✔️ The line smoothly transports potatoes to the slicing machine while minimizing damage and friction.

✔️ The built-in water basin helps remove initial dirt and protects the potatoes during transportation.

✔️ The system maintains the quality of the potatoes before they enter the slicing stage.

2️⃣ Strong and Durable Structure

✔️ Made entirely of 304 food-grade stainless steel to resist corrosion and ensure the highest hygiene standards.

✔️ 3mm thick sidewalls ensure protection and stability during operation.

✔️ 4 mm thick profile frame to support heavy loads and maintain durable operation.

3️⃣ High-performance with a powerful motor

✔️ Power: 2.25 kW – 380/220 V – 50 Hz.

✔️ High-efficiency motor to ensure continuous potato transfer without failure.

✔️ Advanced electrical drive system to ensure stable performance and a long service life.

4️⃣ Practical and Easy-to-Maintain Design

✔️ Easy cleaning and maintenance to ensure efficient production.

✔️ Ergonomic design allows for easy control of potato flow into the slicing machine.

✔️ High-quality materials ensure clean and safe operation in a food manufacturing environment.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to ensure durability and hygiene.

✅ Dimensions:

✔️ Length: 300 cm

✔️ Width: 100 cm

✔️ Height: 200 cm

✅ Machine Number: 006

✅ Model: THV-2024PV-B

✅ Country of Origin: Turkey

✔️ Smooth potato transfer with reduced damage thanks to the built-in water tank.

✔️ Sturdy 304 food-grade stainless steel construction for corrosion resistance and the highest levels of hygiene.

✔️ High-performance motor for continuous operation and high efficiency.

✔️ Practical and easy-to-maintain design for a long machine life.

✔️ Ideal for industrial potato production lines that require precision and high-quality transfer.

💡 The perfect solution for efficiently transferring potatoes to the cutting machine while maintaining their quality!

Sorting Vibrator

Precise sorting of potatoes to ensure smooth and even feeding. The sorting vibrator is an essential component of the potato production line. It separates and sorts the potatoes smoothly along a dedicated path, preventing clumping and ensuring a consistent flow of potatoes during the production process. The device relies on high-frequency vibrations to avoid random feeding and achieve maximum efficiency. Mechanism of Operation:

1️⃣ Four-stage progressive sorting. The vibrator operates according to a step-by-step system to ensure even and orderly potato distribution, facilitating subsequent production processes.

2️⃣ Reduces stacking and random feeding. Thanks to high-frequency vibrations, the stacking of potatoes on top of each other is prevented, maintaining a smooth and continuous flow.

3️⃣ Durable and hygienic design. Made entirely of 304 food-grade stainless steel to ensure maximum hygiene and quality, with a robust construction for reliable performance and sustainability. Technical Specifications:

✅ Material: Made entirely of 304 food-grade stainless steel to ensure hygiene and quality.

✅ Power: 3.75 kW | 380/220V | 50Hz.

✅ Dimensions: Length: 300 cm, Width: 80 cm, Height: 210 cm

✅ Machine Number: 010

🔢 Model: THV-2024PV-B

✅ Country of Origin: Turkey. Features of the Sorting Vibrator:

✔️ Accurate sorting of potatoes to ensure organized feeding.

✔️ Prevents stacking and random feeding thanks to high-frequency vibrations.

✔️ Made entirely of food-grade stainless steel to ensure hygiene and safety.

✔️ Highly efficient operation to facilitate continuous production processes.

💡 The ideal solution for efficiently sorting potatoes and ensuring smooth flow in the production line.

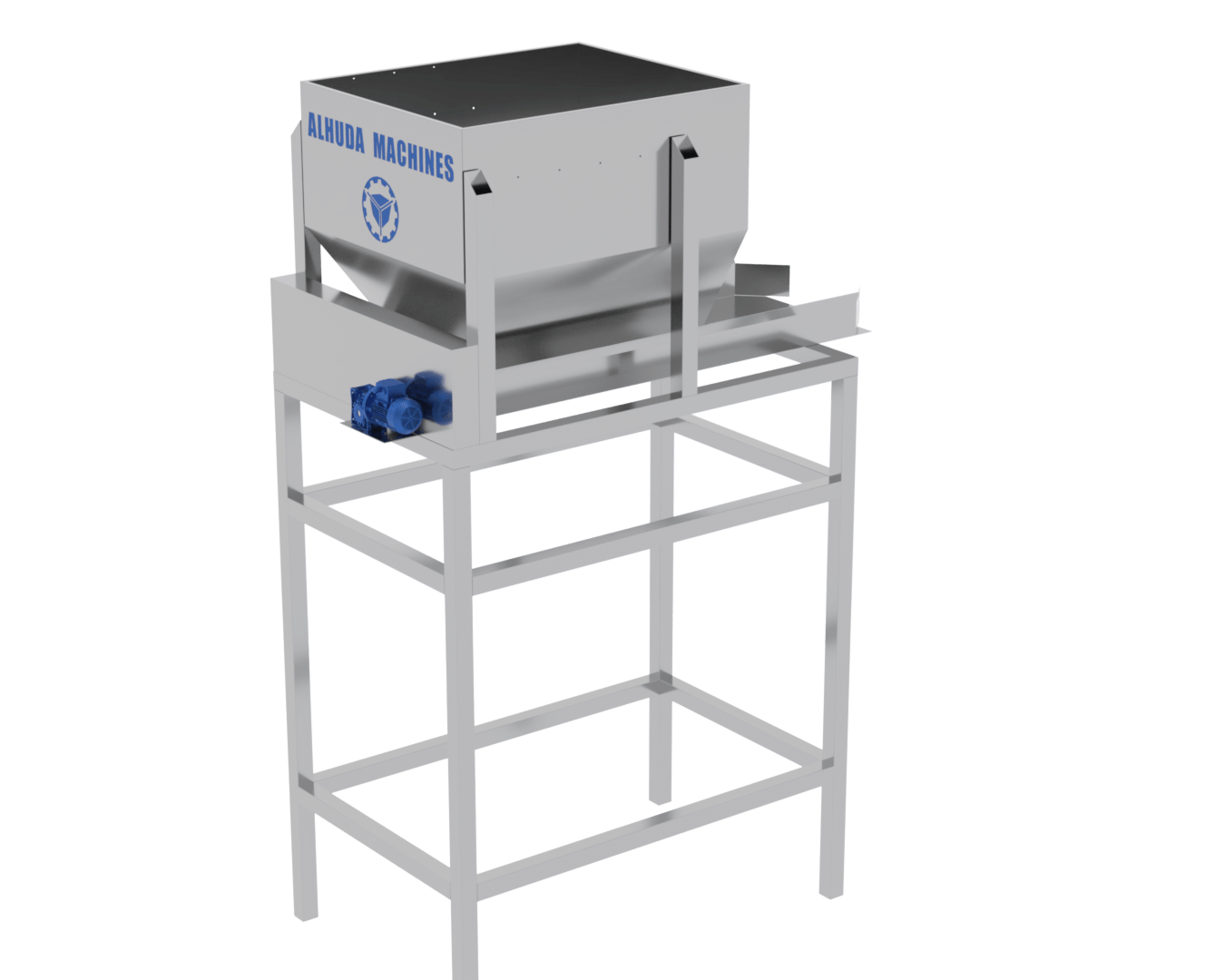

Slicer Feeder

A key step in ensuring consistent feeding of the slicing machine and protecting its components, the slicing feeder feeds potatoes into the slicing machine evenly, preventing random feeding that could damage the slicing machine. This system regulates the flow of potatoes and ensures the line operates efficiently from start to finish without interruption, making it an essential part of improving performance and productivity.

⚙️ Advanced Operation Mechanism:

1️⃣ Precise Feeding and Damage Prevention

✔️ Ensures even feeding of potatoes into the slicing machine without excessive pressure or mess.

✔️ Prevents malfunctions caused by random feeding, prolonging the life of the slicing machine.

✔️ Contributes to continuous, uninterrupted line operation, enhancing productivity.

2️⃣ Strong and Durable Structure

✔️ Made entirely of food-grade 304 stainless steel to resist corrosion and ensure the highest standards of hygiene.

✔️ Robust engineering design ensures stability and stability during operation.

3️⃣ High Performance with a Powerful Motor

✔️ Electrical Power: 1.5 kW – 380/220 V – 50 Hz.

✔️ Powerful motor ensures stable operation and high feeding efficiency.

✔️ Advanced electrical system provides low energy consumption with high performance.

4️⃣ Practical and Easy-to-Maintain Design

✔️ Easy cleaning and maintenance to ensure efficient production.

✔️ Design allows precise control of potato flow into the slicing machine.

✔️ Corrosion-resistant structure provides a long machine life.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to ensure durability and hygiene.

✅ Dimensions:

✔️ Length: 130 cm

✔️ Width: 70 cm

✔️ Height: 180 cm

✅ Machine Number: 007

✅ Model: THV-2024PV-B

✅ Country of Origin: Turkey

✔️ Regular potato feeding prevents breakdowns and preserves the life of the slicing machine.

✔️ Made of food-grade 304 stainless steel to ensure hygiene and durability.

✔️ Powerful motor for continuous operation and high efficiency.

✔️ Practical and easy-to-maintain design to ensure continuous operation without interruption.

✔️ An essential component in improving the efficiency of a production line from start to finish.

💡 The perfect solution for regulating potato feeding and protecting your slicing machine from damage!

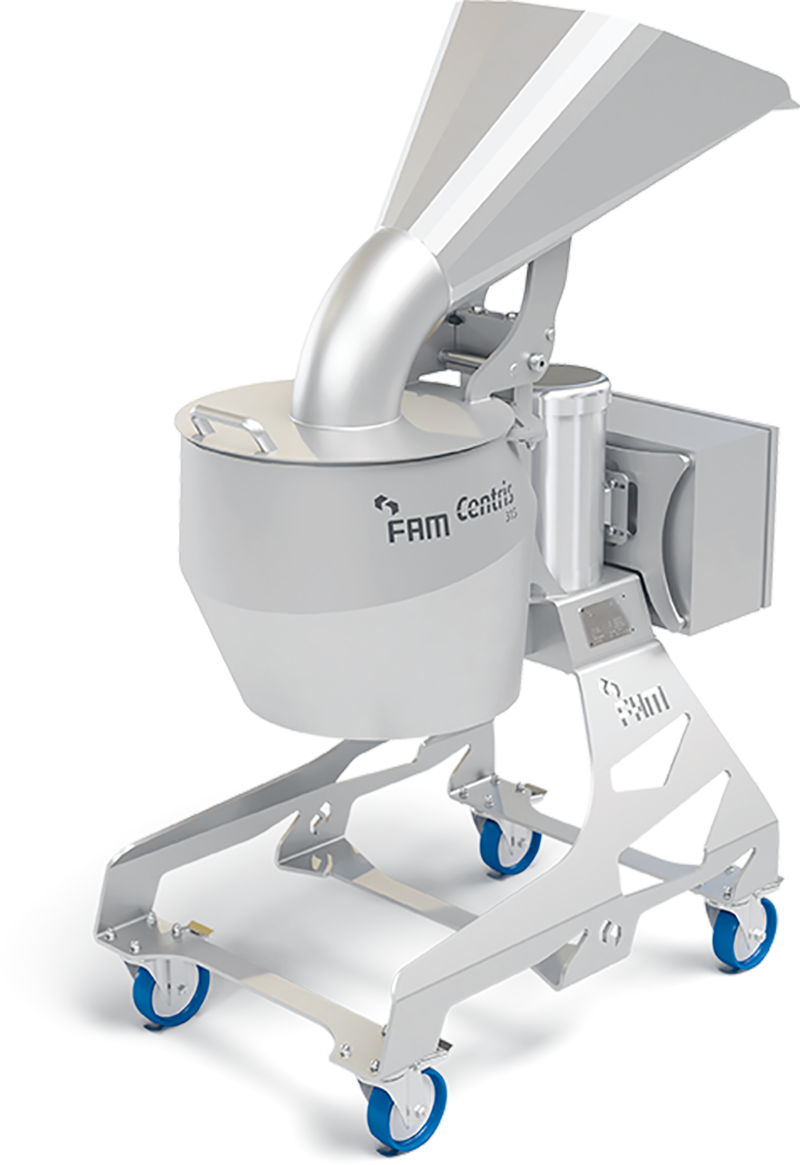

FAM European Potato Slicer

High-precision potato slicing with premium European quality. The Belgian-made FAM slicing machine ensures perfect slicing of potatoes without any surface damage, reducing waste and increasing production efficiency. It produces plain and zigzag slices with a smooth surface and high cutting speed, making it the ideal choice for industrial potato production lines. Thanks to its intelligent design, the machine offers ease of operation and cleaning, saving time and money.

⚙️ Advanced Operation Mechanism:

1️⃣ Precise and High-Quality Slicing

✔️ Professional slicing without damaging the potato surface, maintaining quality.

✔️ Produces plain and zigzag slices with a smooth, uniform surface.

✔️ Fast and efficient slicing, reducing waste and increasing productivity.

2️⃣ Easy Operation and Cleaning

✔️ Ergonomic design facilitates machine operation with minimal effort.

✔️ Sliced potato slices are easy to wash, enhancing the hygiene of the final product.

✔️ Easy to disassemble and assemble, saving time during maintenance and cleaning.

3️⃣ High Performance with Adjustable Thickness

✔️ Adjustable slice thickness as needed for perfect results.

✔️ 1,500 knives per type are included with the machine to ensure continuous operation at the highest efficiency.

✔️ Powerful motor ensures high cutting speed and consistent performance.

4️⃣ Durable and Rust-Resistant Structure

✔️ Made entirely of food-grade 304 stainless steel to ensure hygiene and durability.

✔️ High corrosion resistance, ensuring a long machine life.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to maintain hygiene and quality.

✅ Dimensions:

✔️ Length: 120 cm

✔️ Width: 100 cm

✔️ Height: 150 cm

✅ Power: 1.5 kW – 380/220 V – 50 Hz

✅ Machine Number: 008

✅ Model: THV-2024PV-B

✅ Country of Origin: Europe – Made in Belgium by FAM

💡 Why choose the FAM THV-2024PV-B Potato Slicer?

✔️ Professional slicing without surface damage, preserving potato quality.

✔️ Capable of producing plain and zigzag slices quickly and efficiently.

✔️ Advanced European design by FAM to ensure the highest quality standards.

✔️ Adjustable slice thickness to achieve the desired results.

✔️ Made of food-grade 304 stainless steel for hygiene and easy maintenance.

✔️ Save time and money thanks to ease of operation, cleaning, and maintenance.

🔹 The perfect solution for cutting potatoes with the highest quality and production efficiency!

Potato Starch Stripping Machine

Potato Finger Starch Removal Machine – THV-2024PV-B is an essential step in removing starch and sugars from potatoes before frying, ensuring high quality and perfect taste. The starch removal machine is one of the most important pieces of equipment in potato production lines. It removes starch and sugars stuck to potato slices using high-pressure water mixed with air, improving the final texture of French fries and preventing slices from sticking during frying. The machine uses an advanced water jet system that moves potatoes inside a cylindrical tank equipped with high-pressure water and air pumps, ensuring a deep and effective cleaning of each slice before frying. Additionally, the machine offers the ability to adjust the duration of potato storage, allowing the process to be adapted to different potato types and slice sizes.

⚙️ Advanced Operation Mechanism:

1️⃣ Precision Cleaning System with Jacuzzi Technology

✔️ Potato slices are passed through a high-pressure water jet mixed with air to ensure the removal of starch and stuck sugars.

✔️ The movable cylindrical tank design helps move the slices and prevent them from sticking together during washing.

✔️ The cleaning process is carried out in two stages to ensure complete removal of starch residue, improving the final texture of the fries when fried.

2️⃣ Controllable Processing Time

✔️ The time the potatoes remain inside the machine can be adjusted based on the potato type and slice size, providing high operational flexibility.

✔️ Equipped with a motor that controls the conveyor speed using an inverter to precisely adjust the slice flow.

3️⃣ High-Performance Water and Air Pumps

✔️ Equipped with a high-pressure air pump to move the slices and prevent them from accumulating inside the machine.

✔️ Equipped with a powerful high-pressure water pump with adjustable sprinklers that control the pressure and spray direction to ensure optimal water distribution.

✔️ Starch removal is continuous with a starch collection and removal system, maintaining process efficiency.

4️⃣ Advanced Engineering Design and Easy Maintenance

✔️ An integrated hydraulic system allows the moving part to be raised and lowered safely using four hydraulic pistons powered by oil pressure.

✔️ An ergonomic design allows for easy cleaning and periodic maintenance to ensure continued operation at peak efficiency.

📏 Technical Specifications:

✅ Material: Made entirely of 304 food-grade stainless steel for corrosion resistance and the highest hygiene standards.

✔ Dimensions:

✔️ Length: 500 cm

✔️ Width: 130 cm

✔️ Height: 200 cm

✅ Electric Power: 5.25 kW – 380/220 V – 50 Hz

✅ Number of Motors: 2 – 10 HP each

✅ Machine Number: 009

✅ Model: THV-2024PV-B

✅ Country of Origin: Turkey

✔️ Improves potato quality by removing starch and sugars to reduce stickiness and improve texture after frying.

✔️ A powerful whirlpool cleaning system ensures thorough and effective washing of all slices.

✔️ Adjustable processing time to suit different potato types and slice sizes.

✔️ Equipped with powerful water and air pumps to ensure smooth flow and thorough cleaning.

✔️ An advanced hydraulic system allows the moving part to be raised and lowered easily and safely.

✔️ Designed with 304 food-grade stainless steel for durability and easy cleaning and maintenance.

✔️ A continuous starch collection system prevents clogging of the sprinklers and maintains consistent machine performance.

💡 The perfect solution for removing starch from potato slices before frying and ensuring a high-quality final product!

Water Drying and Slice Separation Vibrator

Effectively removing excess water and flattening chips before frying. The vibrating machine is an essential piece of equipment in potato production lines. It helps dry potato chips after boiling using high-frequency vibration, ensuring quick and efficient removal of excess water. Furthermore, the machine prevents chips from sticking together, facilitating their smooth transfer to the next processing stage. Thanks to its intelligent design, the machine is equipped with a special basin to collect the water separated from the chips during the vibration process, ensuring a clean working environment and high operating efficiency. It is also ideal for handling fragile materials such as potato chips, maintaining product integrity without causing breakage or damage to the chips.

⚙️ Advanced Working Mechanism:

1️⃣ Effective Drying and Excess Water Removal

✔️ It uses high-frequency vibration technology to ensure rapid water removal without the need for heat.

✔️ It is equipped with a water collection basin at the bottom to prevent liquid buildup and maintain a clean working environment.

✔️ The drying process helps improve frying quality and reduce oil absorption, making the product crispier.

2️⃣ Slice Separation to Prevent Sticking

✔️ The machine prevents potato slices from sticking together, ensuring a smooth and even flow to the next machine.

✔️ It moves the slices evenly to ensure uniform distribution and reduce waste during transportation.

3️⃣ Ideal for Fragile and Delicate Materials

✔️ A special design ensures gentle handling of potato chips without breaking them or damaging their shape.

✔️ A balanced vibration system allows for control of vibration intensity to suit different chip types.

4️⃣ Durable and Easy-Maintainable Structure

✔️ Made entirely of food-grade 304 stainless steel to resist corrosion and ensure the highest hygiene standards.

✔️ An ergonomic design facilitates easy cleaning and periodic maintenance to ensure continued operation at peak efficiency.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to maintain hygiene and quality.

✅ Dimensions:

✔️ Length: 170 cm

✔️ Width: 100 cm

✔️ Height: 160 cm

✅ Power: 2.25 kW – 380/220 V – 50 Hz

✅ Machine Number: 010

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

✔️ Effectively removes excess water using high-frequency vibration.

✔️ Prevents chips from sticking to each other to ensure a smooth and even flow.

✔️ Ideal for handling fragile materials such as potato chips without damaging them.

✔️ Improves frying quality by reducing moisture content before chips enter the oil.

✔️ Durable food-grade 304 stainless steel design ensures hygiene and easy maintenance.

✔️ Built-in water collection basin to maintain a clean work environment and high operating efficiency.

💡 The perfect solution for drying and flattening potato chips before frying to ensure a high-quality final product!

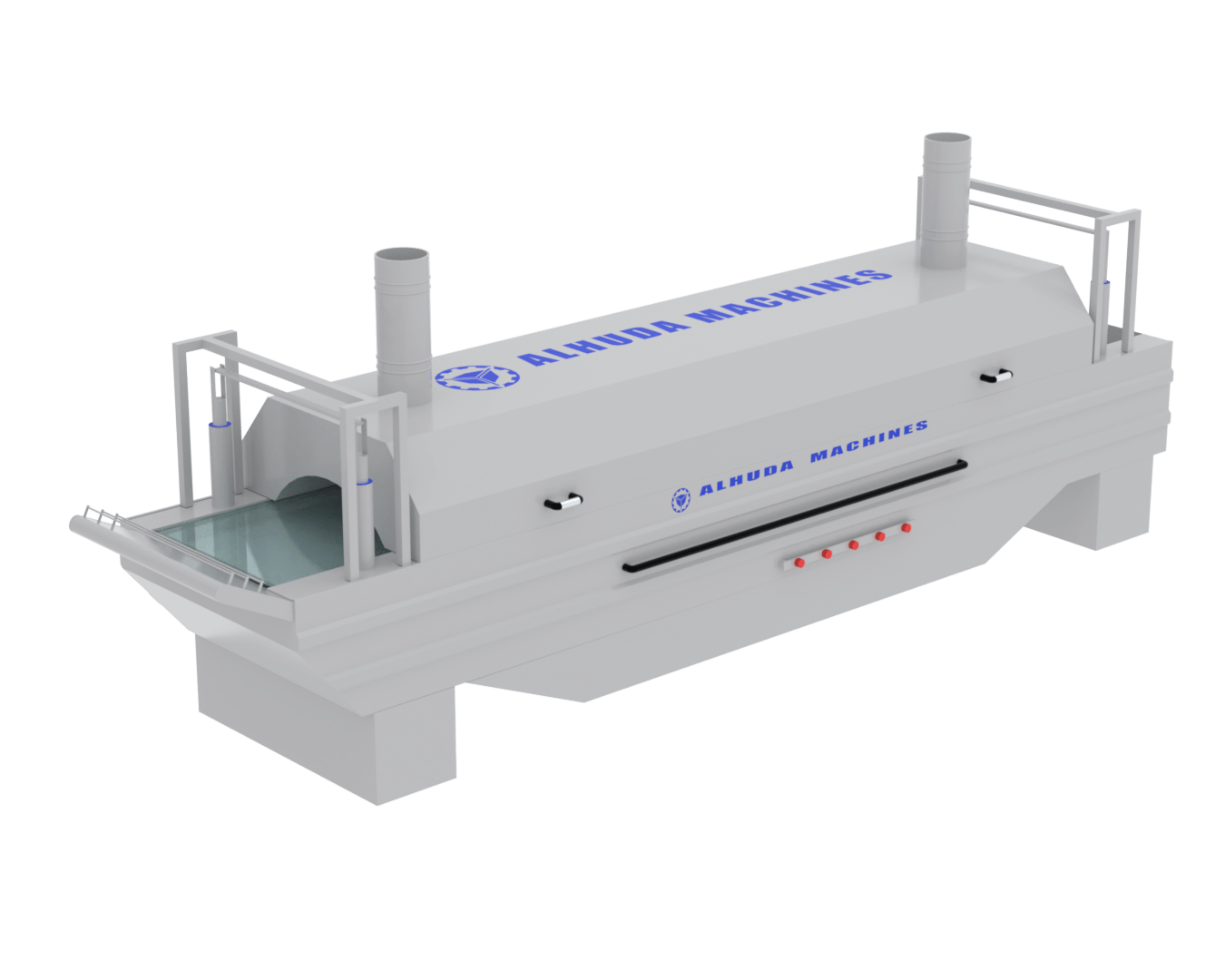

Hot Air Drying Tunnel

Advanced Technology for Drying Potato Chips and Ensuring Perfect Crispness Before Frying. The hot air drying tunnel is one of the most important pieces of equipment in French fries production lines. It removes excess moisture and water from inside potato chips by exposing them to hot air currents, improving the quality of the final product and ensuring perfect crispness after frying. This system helps reduce the water content inside the potatoes before they enter the frying stage, which helps speed up the frying process, saves oil consumption, and prevents oil contamination due to moisture residue. The tunnel features an intelligent design equipped with electric heaters and six fans operating in a closed-circuit system to enhance heat retention, improving drying efficiency and saving energy.

⚙️ Advanced Working Mechanism:

1️⃣ Moisture Removal to Maintain Crispness

✔️ The system dries potato chips by exposing them to evenly distributed hot air currents.

✔️ It helps extract moisture from inside the potato chips, improving the final texture of the fries when fried.

✔️ It reduces the water content inside the chips, preventing lumps from forming and sticking together during frying.

2️⃣ Advanced Heating System with High Thermal Efficiency

✔️ Equipped with powerful electric heaters to ensure efficient air heating.

✔️ 6 powerful fans operate in a closed circuit to improve heat retention, accelerating the heating process.

✔️ Balanced air pressure to ensure even heat distribution across all slices.

3️⃣ Improved Frying Efficiency and Maintain Oil Quality

✔️ Helps reduce oil absorption, prolonging the life of the frying oil and keeping it clean.

✔️ Prevents oil contamination from excess moisture, improving the taste and quality of French fries.

4️⃣ Durable and Easy-Maintain Design

✔️ Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and corrosion resistance.

✔️ Easy to clean and maintain for continued, efficient operation.

📏 Technical Specifications:

✅ Material: Made entirely of 304 food-grade stainless steel for corrosion resistance and the highest hygiene standards.

✅ Dimensions:

✔️ Length: 400 cm

✔️ Width: 100 cm

✔️ Height: 160 cm

✅ Power: 9.75 kW – 380/220 V – 50 Hz

✅ Number of Fans: 6 powerful closed-circuit fans

✅ Machine Number: 011

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

✔️ Removes moisture quickly and efficiently, improving frying quality and ensuring perfect crispiness.

✔️ Improves oil consumption and prevents oil contamination, extending oil life and reducing production costs.

✔️ Equipped with powerful electric heaters with 6 closed-circuit fans to maintain high thermal efficiency.

✔️ Prevents chips from sticking together and ensures even heat distribution.

✔️ Durable, food-grade 304 stainless steel construction ensures durability and easy cleaning and maintenance.

✔️ Advanced air pressure control ensures even drying without affecting the shape of the chips.

💡 The perfect solution to ensure moisture is removed from potato chips before frying, resulting in a high-quality final product with perfect crispness!

Continuous frying

The latest continuous frying technology ensures optimal quality and high production of potato chips. The continuous fryer is one of the most important stages of the French fries production line. It fries potato chips in an oil bath using an advanced heating system that maintains the ideal temperature, ensuring even cooking and a crispy texture. The oil is heated using a heat exchanger (boiler) outside the fryer to maintain oil quality and prevent burning. The fryer also features continuous stirring of the potatoes inside the oil to ensure complete immersion and homogeneous heat distribution. After frying is complete, the potatoes are transferred via a conveyor to the next stages of the production line. The fryer is equipped with the latest safety and control systems, including a PID system to ensure temperature stability, as well as an advanced protection system that enables the potatoes to be removed from the fryer even in the event of a power outage to prevent product burning in emergency situations.

⚙️ Advanced Operation Mechanism:

1️⃣ Advanced Heating System to Maintain Oil Quality

✔️ The oil is heated via an external heat exchanger (boiler), maintaining a constant temperature without directly exposing the oil to the heating source, preventing scorching and extending its shelf life.

✔️ Precise temperature control via a PID system ensures consistent temperature throughout the frying process.

✔️ A three-stage oil filtration system continuously purifies the oil during frying, maintaining its quality and purity.

2️⃣ Continuous Stirring to Ensure Even Frying

✔️ The potatoes move continuously inside the fryer to ensure full exposure to the hot oil, achieving even frying for all slices.

✔️ The belt speed is controlled by inverter-controlled motors to suit different potato types and sizes.

✔️ The fryer is equipped with 10 motors with an inverter speed controller to ensure high performance and precise control of potato flow.

3️⃣ Integrated Industrial Safety System

✔️ A power-off protection system automatically removes potatoes from the fryer even without electricity to prevent product burns.

✔️ A 15 cm thick fiberglass thermal insulation layer covers all parts of the fryer to ensure safety and protect workers from high temperatures.

✔️ The fryer is designed with two oil vapor outlets to prevent moisture buildup and ensure a healthy and safe working environment in accordance with occupational health and safety standards.

4️⃣ Robust and Multifunctional Design

✔️ Two double jacket oil recovery tanks, each with a capacity of 800 liters for new oil and 800 liters for used oil recovery, are equipped with heaters to maintain oil temperature.

✔️ The conveyor belt is equipped with an inverter-controlled speed motor to ensure precise control of frying time.

✔️ The fryer is equipped with drain holes for waste oil, facilitating maintenance and cleaning.

✔️ The moving part of the fryer can be safely raised and lowered using 6 hydraulic pistons powered by oil pressure.

📏 Technical Specifications:

✅ Material: Made entirely of 304 and 316 food-grade stainless steel to withstand high temperatures and ensure hygiene.

✅ Dimensions:

✔️ Length: 850 cm

✔️ Width: 130 cm

✔️ Height: 200 cm

✅ Oil capacity inside the fryer: 1200 liters

✅ Electricity: 9.75 kW – 380/220 V – 50 Hz

✅ Number of motors: 10 motors with inverter speed control

✅ Thermal insulation system: 15 cm thick fiberglass layer

✅ Filtration system: Three stages for continuous oil purification

✅ Control system: PID to maintain a constant temperature

✅ Lifting system: 6 hydraulic pistons for safe movement

✅ Machine number: 012

✅ Model: THV-2024PV-B

✅ Country of origin: Turkey

💡 Why choose the THV-2024PV-B continuous fryer?

✔️ Precise temperature control via PID to maintain product quality

✔️ Continuous stirring system to ensure even frying of all potato slices.

✔️ Advanced three-stage oil filtration system to maintain oil quality and reduce waste.

✔️ Power-off protection to prevent product burnout.

✔️ Strong 15 cm thermal insulation to ensure industrial safety and reduce energy consumption.

✔️ Easy opening and maintenance thanks to an innovative design that allows the moving part to be safely lifted.

✔️ Two oil vapor outlets to provide a healthy and safe working environment.

✔️ Large oil capacity of up to 1200 liters with 800-liter compensation tanks for new oil and 800 liters for used oil recovery.

💡 The ideal solution for high-quality potato frying, with advanced technologies to ensure stable production and excellent operational efficiency!

Oil Drying Vibrator

The latest oil drying technology to ensure perfect quality and high production of potato chips The oil drying vibrating ... ✔️ It works according to a gradual four-stage process to ensure balanced oil filtration and achieve ideal results. ✔️ Prevents potato chips from sticking to each other and reduces the rate of breakage during transportation and processing. 2️⃣ Healthy and durable design according to the highest standards ✔️ Made entirely of 304 food grade stainless steel to ensure hygiene and rust resistance. ✔️ Easy to clean and maintain design, ensuring continued operating efficiency for the longest possible period. ✔️ Ensures even vibration flow, which helps improve the overall efficiency of the production line. 3️⃣ Economical energy consumption and high performance ✔️ Powerful motor provides balanced vibration to ensure ideal results. ✔️ Equipped with an advanced system to control the intensity of vibration to suit the type and size of potato chips produced. 4️⃣ Engineering design that ensures ease of operation and maintenance ✔️ Equipped with four gradual stages of oil filtration, which contributes to improving drying efficiency. ✔️ Equipped with a precise control mechanism that ensures stable operation and reduces production loss. ✔️ Compact and robust design allows easy integration into modern production lines. 📏 Technical Specifications: ✅ Material: Made entirely of 304 food grade stainless steel to ensure high heat resistance and easy cleaning. ✅ Dimensions: ✔️ Length: 300 cm ✔️ Width: 100 cm ✔️ Height: 140 cm ✅ Power: 4.5 kW – 380/220 V – 50 Hz ✅ Gradual flow: Four stages for efficient oil filtration. ✅ Machine No.: 013 ✅ Model: THV-2025PV-B ✅ Country of Origin: Turkey ✔️ High frequency vibration technology to efficiently and effectively remove excess oil. ✔️ Hygienic design made of 304 food grade stainless steel for rust resistance and easy cleaning. ✔️ Gradual flow of four stages for balanced oil filtration. ✔️ Economical energy consumption with stable operating performance. ✔️ Advanced vibration intensity control system to suit the quality and size of the chips produced. ✔️ Reduces the sticking of potato chips to each other and prevents breakage during transportation and processing. ✔️ Robust design ensures easy operation and maintenance. 💡 The ideal solution for drying potato chips and ensuring stable production with high quality and perfect operational efficiency!

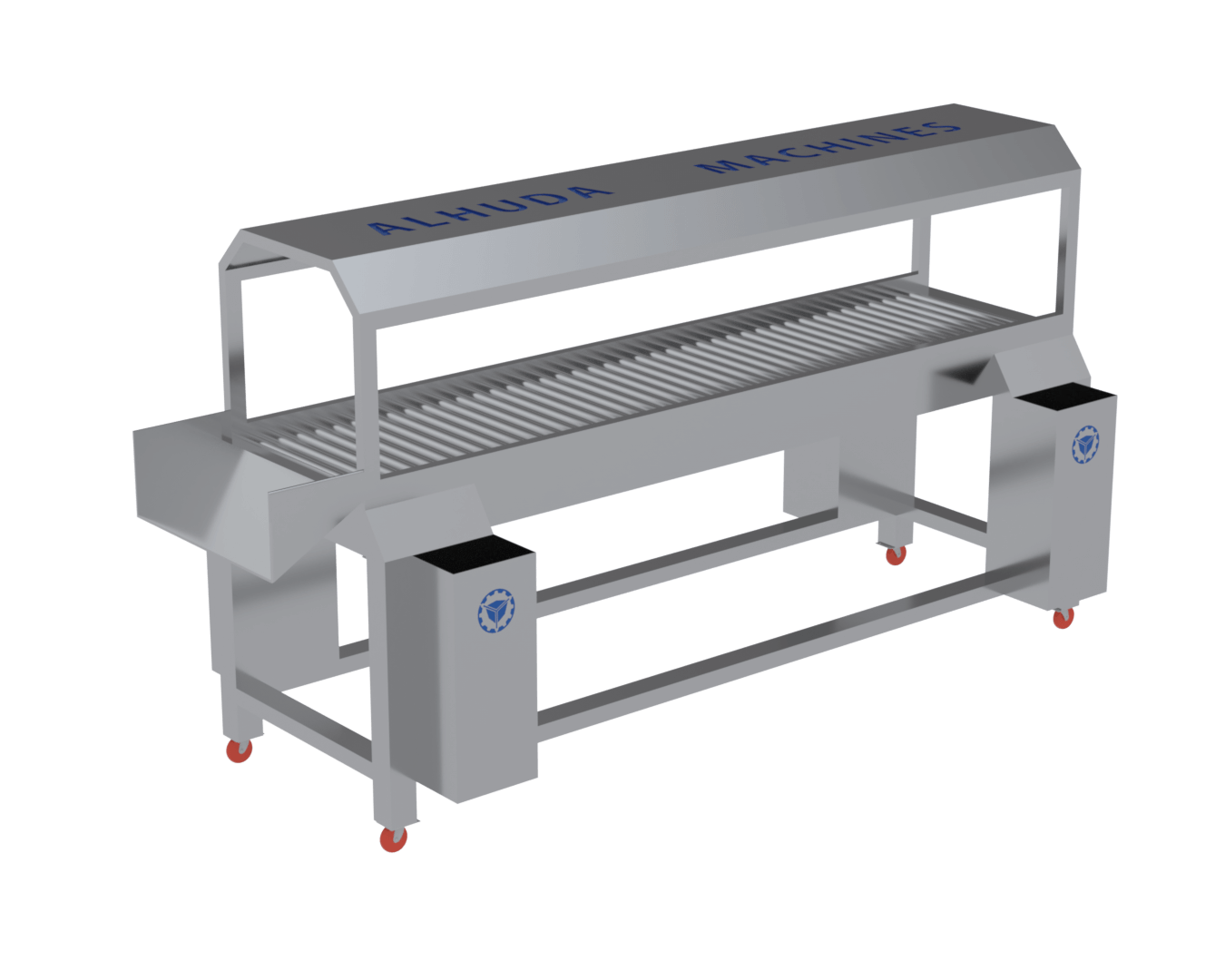

Inspection Line

The latest technology for inspecting potato chips to ensure product quality before packaging The inspection line is one of the essential stages in the potato chips production line, as it aims to ensure product quality by removing black spots and unwanted slices before entering the flavor and packaging stage. This system contributes to improving the quality of the final product and reducing the percentage of waste, which ensures obtaining homogeneous and ideal-looking potato chips. The line is designed from food-grade 304 stainless steel to ensure food hygiene and health standards, and is easy to clean and maintain to ensure continuous operation with high quality. ⚙️ Advanced working mechanism: 1️⃣ Accurate inspection system to ensure quality ✔️ The conveyor line sorts potato chips manually or automatically to ensure the removal of unsuitable slices or those containing black spots. ✔️ It contributes to improving the appearance and quality of the final product before moving to the flavor and packaging stage. ✔️ It helps reduce the percentage of waste and increase production efficiency by getting rid of non-conforming pieces. 2️⃣ Hygienic and durable design according to the highest standards ✔️ Made entirely of 304 food grade stainless steel to resist rust and ensure food safety standards. ✔️ Easy to clean and maintain, ensuring continuous operation of the line with high quality. ✔️ Flat surface to facilitate the sorting and inspection process manually or via smart cameras (in case of integrating optical sorting systems). 3️⃣ Operational efficiency with low energy consumption ✔️ Designed to achieve smooth movement of slices to ensure efficient sorting without disrupting the flow of production. ✔️ Compatible with modern production systems and can be easily integrated with the rest of the production line equipment. 4️⃣ Engineering design that ensures ease of operation and maintenance ✔️ Conveyor line 500 cm long and 100 cm wide, providing sufficient working space for sorting and accurate inspection. ✔️ Suitable height (130 cm) allows for easy manual supervision of the inspection process. ✔️ Can be integrated with smart cameras or advanced sorting systems to improve sorting efficiency and reduce the need for manual intervention. 📏 Technical Specifications: ✅ Material: Made entirely of 304 food grade stainless steel to ensure high heat resistance and easy cleaning. ✅ Dimensions: ✔️ Length: 500 cm ✔️ Width: 100 cm ✔️ Height: 130 cm ✅ Power: 1.125 kW – 380/220 V – 50 Hz ✅ Manual or automatic sorting system to ensure the highest quality. ✅ Machine Number: 014 ✅ Model: THV-2024PV-B ✅ Country of Origin: Turkey ✔️ Ensures the removal of unwanted slices and improves product quality before packaging. ✔️ Made of 304 food grade stainless steel for easy cleaning and rust resistance. ✔️ Contributes to reducing waste and improving production efficiency. ✔️ Low energy consumption with stable operating performance. ✔️ Possibility of integrating intelligent optical sorting systems to improve inspection efficiency and reduce the need for manual intervention. ✔️ Durable and easy to maintain design to ensure continuous operation with high quality. 💡The perfect solution to ensure the production of high quality potato chips and optimal operational efficiency!

Chips Flavoring Device

🚀 The latest flavor distribution technology ensures a consistent taste and optimal quality for potato chips. The flavoring device is an essential component of the potato chips production line, ensuring the even distribution of flavor powder throughout the chips, achieving a balanced taste and optimal quality for the final product. The device relies on a precision feeding system using a horizontal screw equipped with an inverter, allowing complete control over the amount of flavor flowing into the spray unit. The flavor is evenly sprayed onto the potato chips as they move through the device. The device is constructed from food-grade 304 stainless steel in compliance with the latest health and safety standards, ensuring optimal hygiene and ease of cleaning and maintenance.

⚙️ Advanced Operation Mechanism:

1️⃣ Precision feeding system for optimal flavor distribution

✔️ Equipped with a tank with a mixing and stirring device to ensure the flavor powder is homogeneous before being transferred to the spray unit.

✔️ It relies on a horizontal feeding screw equipped with an inverter, allowing precise control of the flavoring quantity dispensed according to production requirements.

✔️ The flavor is sprayed via a precise vibrating unit, ensuring even distribution throughout each chip.

2️⃣ Hygienic and durable design to the highest standards

✔️ Made entirely of food-grade 304 stainless steel to ensure rust resistance and easy cleaning.

✔️ Designed to efficiently distribute the flavor powder, completely covering the chips without leaving any exposed areas.

✔️ A compact and robust structure ensures consistent operation.

3️⃣ Operational efficiency with advanced electronic control

✔️ Equipped with an intelligent electronic circuit to accurately calibrate and adjust the flavoring quantity dispensed.

✔️ The flavoring quantity can be controlled via an inverter to adjust the flavor according to market requirements.

✔️ Economical energy consumption with high operational efficiency.

4️⃣ Ease of Operation and Maintenance

✔️ Compact design allows for easy opening and cleaning to ensure consistent, high-quality operation.

✔️ Easily integrates with various production lines to provide a smooth and consistent flavor flow.

✔️ Advanced spraying system prevents powder buildup inside the machine, facilitating periodic maintenance and cleaning.

📏 Technical Specifications:

✅ Material: Made entirely of 304 food-grade stainless steel to ensure high resistance and easy cleaning.

✅ Dimensions:

✔️ Length: 140 cm

✔️ Width: 80 cm

✔️ Height: 160 cm

✅ Power: 2.25 kW – 380/220 V – 50 Hz

✅ Horizontal spiral feeding system with an inverter to control the amount of flavor flowing.

✅ Machine Number: 015

✅ Model: THV-2024PV-B

✅ Country of Origin: Turkey

✔️ Precise control of the amount of flavor flowing through an inverter-equipped spiral feeding system.

✔️ Optimal distribution of flavor powder to ensure complete and even coverage of each chip.

✔️ Made of food-grade 304 stainless steel for maximum hygiene and easy cleaning.

✔️ Advanced electronic control system for precise adjustment and calibration.

✔️ Compact and easy-to-maintain design for continuous, uninterrupted operation.

✔️ Compatible with various production lines and customizable according to factory requirements.

💡 The ideal solution for ensuring consistent taste and optimal quality of potato chips with high operational efficiency!

Flavor coating roller

🚀 Advanced technology for flavoring potato chips, ensuring consistent flavor distribution with high quality. The seasoner (flavoring drum) is one of the most important pieces of equipment in the potato chip production line. It distributes the flavor powder evenly throughout the chips, ensuring a balanced, high-quality taste. The seasoner is designed from food-grade 304 stainless steel and features an electronic inverter control system to adjust the rotation speed. This allows for controlling the time the chips pass through the drum to ensure maximum absorption and flavor coverage. It is also equipped with an advanced, calibrated American flavor sprayer, enabling highly accurate flavor distribution without waste or clumping.

⚙️ Advanced working mechanism:

1️⃣ Balanced rotation system to ensure complete flavor coverage

✔️ The seasoner rotates the potato chips slowly and evenly while spraying the flavor, preventing powder accumulation in specific areas and ensuring optimal distribution.

✔️ Equipped with special internal scales that prevent flavor aggregation and clumping, enhancing distribution efficiency and giving the final product a consistent taste.

✔️ Calibrated to control the time the chips pass through, allowing the flavor level to be adjusted according to production requirements.

2️⃣ Advanced American Flavor Spray System

✔️ Equipped with a high-precision, calibrated flavor spray that allows complete control over the amount of flavor dispensed.

✔️ Prevents unwanted powder buildup, reducing waste and improving final product quality.

✔️ Operates efficiently to ensure even flavor distribution throughout the chips.

3️⃣ Removal of Impurities and Unwanted Small Chips

✔️ The flavoring cylinder is equipped with a mechanism to eject impurities and very small chips, which may form during the production process.

✔️ This system maintains final product quality by removing broken and non-conforming pieces.

4️⃣ Practical Design for Easy Operation and Maintenance

✔️ Equipped with a chrome cover for the material outlet, making it easy to empty the finished chips without losing any flavor.

✔️ Wheels for easy movement and cleaning, ensuring flexible operation and easy maintenance.

✔️ Hygienic design made of food-grade 304 stainless steel, ensuring corrosion resistance and easy cleaning after operation.

📏 Technical Specifications:

✅ Dimensions:

✔️ Length: 300 cm

✔️ Width: 120 cm

✔️ Height: 150 cm

✅ Electricity: 3.75 kW – 380/220 V – 50 Hz

✅ Control System: Equipped with an inverter to adjust the rotation speed according to production requirements.

✅ Advanced Spray System: American-made calibrated flavor sprayer to ensure uniform distribution.

✅ Impurity Removal System: A mechanism that expels unwanted small chips.

✅ Machine Number: 016

✅ Model: THV-2024PV-B

✅ Country of Origin: Turkey

✔️ Precise inverter speed control ensures maximum flavor coverage.

✔️ Advanced American flavor spray ensures even distribution without waste or clumping.

✔️ Internal scales designed to prevent flavor buildup, preserving the quality of the final product.

✔️ A system for removing impurities and small chips, ensuring a clean and consistent product.

✔️ Compact and easy-to-maintain design with wheels for easy movement and cleaning after use.

✔️ Made entirely of food-grade 304 stainless steel according to the highest health and safety standards.

💡 The perfect solution for flavoring potato chips with high operational efficiency and a perfect, consistent taste!

Server conveyor belt

Precise and balanced conveying to maintain product quality. The conveyor belt is one of the most important stages of potato chips production, ensuring efficient product transfer from the flavoring stage to three packaging machines, while preserving the integrity of the chips through a fully automated and precise distribution system. Advanced Operation Mechanism

1️⃣ Precise electronic control system. The product transfer speed is controlled by an electronic control circuit equipped with modern sensors, allowing for balanced product feeding according to the capacity of the packaging machines.

✅ Equipped with a reservoir and vibrator to ensure a consistent flow of chips without accumulation or jamming.

✅ Fully automated to reduce manual intervention and increase production efficiency.

2️⃣ Conveyor belt with an advanced design equipped with a Z-shaped PVC belt to facilitate product transfer at an appropriate angle, helping achieve optimal flow without affecting the shape of the chips.

✅ Made of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Its design reduces vibration and shock, keeping the product unbroken.

3️⃣ Smart sensors for improved performance. Advanced electronic sensors automatically adjust product speed and flow, preventing any buildup or congestion in the production line.

✅ Ensures even product distribution between packaging machines for stable and consistent production.

4️⃣ Durable and easy-to-clean design. Made entirely of food-grade 304 stainless steel to ensure rust resistance and easy cleaning, with a robust structure to withstand continuous operation in industrial environments.

✅ Equipped with sturdy wheels for easy movement and maintenance. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest levels of hygiene and quality.

✅ Electrical Power: 5.25 kW | 380/220 V | 50 Hz

✅ Dimensions: Length: 10 cm, Width: 90 cm, Height: 350 cm

✅ Machine Number: 009

✅ Model: THV-2024PV-B

✅ Country of Manufacture: Turkey Features of the Feeding Conveyor Line

✔️ Precise electronic control system with sensors to automatically adjust the product conveying speed.

✔️ Z-shaped PVC conveyor ensures optimal flow without compromising the quality of the slices.

✔️ Shock and vibration-resistant design to protect the product from breakage.

✔️ Tank and vibrator to ensure consistent flow and prevent product accumulation during conveying.

✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning.

✔️ Equipped with sturdy wheels for easy movement and cleaning, making it ideal for industrial environments.

💡 The perfect solution for efficient product transfer and ensuring the highest levels of production quality!

CONTINUOUS SYSTEM GRAVIMETRIC PACKAGING MACHINES 3PCS

Weighted Packaging Machine – Accurate and Fast Food Packaging with Advanced Systems. The weighted packaging machine is designed according to the latest global technologies to ensure high speed, 24-hour operation, and superior accuracy in weighing and packaging. It features advanced drive systems, precise optical sensors, and an integrated electronic control system that ensures high efficiency and consistent production. Advanced Operation Mechanism:

1️⃣ Precise and flexible packaging system for automatic packaging of potato chips, chips, seeds, and nuts. It relies on an intelligent weighing system to ensure accurate packaging and reduce waste.

2️⃣ Advanced electronic control for smooth operations. Advanced PLC system from Delta for fast response and precise control. 7-inch electronic touch screen from Delta for ease of operation. Precise OMRON thermal control system allows temperature adjustment from the screen to ensure weld quality.

3️⃣ High performance with powerful motors and gearboxes to control the conveyor belt and jaws, ensuring stable operation. Stepper motor for automatic roll-carrying movement controlled via the screen. A stepper motor compensates for roll pull and an alarm system when the roll is finished.

4️⃣ Safe and durable design. Safety sensors protect the operator from any operational errors. A comprehensive daily production counter for performance monitoring and effective production tracking. The entire body is made of 304 food-grade stainless steel to ensure hygiene and product safety. All parts in contact with the product are made of 304 stainless steel in compliance with food quality standards.

5️⃣ Flexible roll usage. Roll width can be customized to suit customer requirements, allowing for the packaging of a variety of products. Maximum roll length: 320 mm. An Italian-made roll forming device is easy to replace to increase operational efficiency. Supports the use of an integrated cellophane roll to ensure tight, high-quality packaging.

6️⃣ Additional equipment to increase efficiency: A Z-shaped PVC conveyor belt with a 304 stainless steel structure and an automatic feeding system. A conveyor belt for finished packages to ensure easy transportation and storage. A date printer to print product information directly onto the package. A smart weighing system from HIGH DREAM ensures high weight accuracy. The weighing platform is made of 304 stainless steel to ensure stability and reliability. Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to maintain hygiene and quality.

✅ Power: 5.75 kW | 380/220 V | 50 Hz.

✅ Dimensions: Length: 200 cm, Width: 130 cm, Height: 420 cm

🔢 Machine Number: 024

✅ Model: THV-2024PV-B

✅ Country of Origin: Turkey. Robust design to ensure high performance:

✔️ High weight accuracy via the smart summation system.

✔️ Comprehensive electronic control for maximum operational efficiency.

✔️ Integrated safety with safety sensors to protect the operator.

✔️ Flexibility in using packaging rolls according to customer needs.

✔️ High-quality European components to ensure machine durability. Features of the Weight Packaging Machine:

✔️ High speed and high accuracy in packaging.

✔️ Advanced PLC electronic control system enables smooth and responsive operation.

✔️ Durable 304 stainless steel construction to ensure cleanliness and product safety.

✔️ Practical and easy-to-maintain design to extend the machine's lifespan.

✔️ Integrated safety systems to ensure operator safety.

💡 The ideal solution for filling and packaging food products with extreme efficiency and precision!

Electrical parts and control panels

Schneider brand cutters Schneider brand contactors delta control screen delta inverters Engines company GAMAK YILMAZ gearboxes Or according to the customer's request

Basic information

🥔💼 Natural Potato Chips Production Project – From Al-Hoda Company. Today, we present to you one of the most powerful, profitable, and widespread industrial projects in various countries and cities. This project is considered one of the most promising in the world of food industries:

🏭 Natural Potato Chips Factory. The high and continuous demand for potato chips (natural chips) makes this project a golden opportunity for every investor looking for a guaranteed and successful production project. Chips are consumed daily by all age groups and are easily distributed in cities, neighborhoods, and even villages, facilitating the sales process even in the presence of major competing companies.

✅ Why is the Natural Chips Project a product in daily and frequent demand? It is not dependent on a specific season or target audience. It can be easily expanded geographically. It is easy to market in stores, grocery stores, and supermarkets. It has a good profit margin and stable operating costs.

🏗️ Natural Potato Chips Production Line – Manufactured by Al-Huda Company

🌟 High Quality and European Technology. At Al-Huda International, we are proud to offer a natural potato chips production line manufactured in Turkey, using advanced German technology and over 20 years of experience in this field.

💡 The line is fully automatic and achieves high-quality production with minimal human intervention, while maintaining the crisp texture and natural flavor of the potatoes.

⚙️ Basic Line Specifications:

🔸 Production Capacity: Starting from 500 kg/hour and up to 2 tons/hour (upon request).

🔸 Number of Shapes: More than 3 different shapes depending on the type of mold used.

🔸 Approximate Line Length: 70 meters.

🔸 Required Width: Approximately 4 meters.

🔸 Installation Area Required: Approximately 500 square meters.

🔌 Electricity consumption: Approximately 130 kW.

🔧 All parts are made of high-quality 304 food-grade stainless steel.

🛡️ Unparalleled Guarantee and Quality: At Al-Huda, we are fully committed to the quality of our production lines. We conduct all tests and trials at our factory in Gaziantep, Turkey. We bear full responsibility for any defects in specifications or performance.

🔄 If the line is not suitable for the customer, they have the right to a refund without obligation.

🏆 Why choose Al-Huda?

✅ Turkish-made with German technology.

✅ Over 20 years of experience in manufacturing chips production lines.

✅ Our products have international quality certifications.

✅ After-sales service and ongoing technical support.

✅ Line testing at the factory before shipping.

✅ Customization and modification options are available to meet customer requirements.

📩 For inquiries and to obtain a detailed catalog, photos, and videos, please feel free to contact us:

💬 Our technical and administrative team is ready to answer all your inquiries and provide you with complete, accurate, and detailed information.

🔚 Al-Huda - Your ideal choice and partner in success to start a successful project with confidence and guaranteed quality.

Gallery