Chips production line oven

⭐ Corn Chip Production Line – 100% Healthy, Hot Air Oven System.

✅ A complete production system for manufacturing corn chips (snacks) made from corn and wheat flour, and natural ingredients such as calcium, sugar, and baking soda. These chips are: 100% healthy, completely oil-free, crispy, light, and appealing to all ages.

🔥 High-Quality Manufacturing: The entire line is designed according to European standards, based on over 20 years of experience, using food-grade 304 stainless steel and German-made components to ensure durability and reliable performance.

⚙️ Extremely Easy Operation: Fully automated operation from mixing the ingredients to packaging. The line is controlled via a smart PLC (Programmable Logic Controller) allowing the operator to precisely control temperature, speed, and timing. Easy maintenance and daily cleaning.

📦 The line can produce over 30 different shapes of snacks, depending on the molds used.

💼 Warranty and Service: At Al Huda Company, we guarantee: the quality of the line and its compliance with specifications; and testing and operation of the line for the customer at our facility.

🛠️ Made in Turkey with German Technology – ISO Certified

The line consists of the following parts

1 – Flour Mixer

2 – Spiral Feeder

3 – Forming Extruder with Automatic Feeding Device

4 – Drilling Machine

5 – 3D Cutter

6 – Steak Cutter

7 – Conveyor Line

8 – Drying and Roasting Oven

9 – Conveyor Line

10 – Flavor Tanks

11 – Flavor Pump

12 – Seasoning Cylinder

13 – Feeder Line for Packaging Machines

14 – Packaging Machines

Flour mixer

An effective industrial solution for mixing dough ingredients precisely and evenly – cylindrical design, high performance, and easy operation and cleaning! The flour mixer is an essential component in food production lines that rely on fine doughs and mixtures. This drum mixer is specially designed to combine basic dough ingredients such as farina flour, water, salt, starch, calcium carbonate, and baking soda, to produce a homogeneous mixture that is easy to transport and shape in the next stages. The mixer is made entirely of food-grade 304 stainless steel, which is resistant to rust and corrosion, and is easy to clean and maintain. It also has a bottom outlet to discharge the dough into a screw conveyor to transport the mixture to the next stage of production.

⚙️ How it works:

1️⃣ Mixing flour and added ingredients

✔️ The mixer combines the farina with water, salt, starch, calcium carbonate, and baking soda to produce a homogeneous and balanced mixture.

2️⃣ Discharging the Mixed Dough

✔️ After mixing is complete, the dough is discharged through a lower opening into a spiral conveyor for direct transport to the next stage.

3️⃣ Hygienic and Easy-to-Clean Design

✔️ Thanks to its cylindrical design and food-grade stainless steel construction, the mixer can be quickly cleaned to ensure maximum hygiene.

📏 Technical Specifications:

✅ Machine Type: Drum Flour Mixer

✅ Mixing Capacity: As Requested (Determined by Line)

✅ Discharge System: Bottom Outlet to Spiral Conveyor

✅ Material: Food-grade 304 stainless steel

✅ Operating System: Electric - 3.75 kW

✅ Voltage: 380/220 VAC - 50 Hz

✅ Dimensions:

✔️ Length: 100 cm

✔️ Width: 90 cm

✔️ Height: 140 cm

✅ Machine Number: 001

✅ Model: THV-2025 PV-B

✅ Country of Origin: Turkey

💡 Why is a flour mixer an essential part of production lines?

✔️ Because it ensures efficient homogeneity of dough ingredients.

✔️ Because it is easy to operate, discharge, and transport.

✔️ Because it is made of hygienic materials suitable for food environments.

✔️ Because it facilitates work on automated lines and saves time.

✔️ Because it is designed to meet the requirements of modern industrial production.

screw conveyor

A smart and safe conveying system for lifting the flour mixture from the mixer to the extruder – large capacity, hygienic design, and high security. The screw conveyor is an essential part of the dough production line, automatically transporting the blended mixture from the flour mixer to the extruder with high efficiency. The system features a 75 kg receiving tank, where the mixture is collected and transferred via a closed screw conveyor designed to prevent any unsafe manual intervention. The screw conveyor is equipped with a metal mesh to protect against hand entry and an advanced magnetic mechanism to remove metal impurities, ensuring product safety and quality. It also features a bottom opening for quick cleaning after operation.

⚙️ Working mechanism:

1️⃣ Mixture reception from the mixer

✔️ The flour mixture is received from the flour mixer outlet into a 75 kg tank.

2️⃣ Automatic transfer to the extruder

✔️ The mixture is lifted via an internal screw conveyor to the extruder without manual intervention.

3️⃣ Complete Protection

✔️ Covered with a metal mesh to prevent the operator's hand from entering the spiral during operation.

✔️ Equipped with a magnetic mechanism to remove any metal impurities present in the mixture.

4️⃣ Easy Cleaning and Maintenance

✔️ Includes a special bottom opening for easy drainage and cleaning of the mixture.

📏 Technical Specifications:

✅ Machine Type: Automatic Spiral Conveyor

✅ Tank Capacity: 75 kg

✅ Safety System: Metal Mesh + Magnetic Mechanism

✅ Discharge System: Bottom Cleaning Hole

✅ Material: Food Grade 304 Stainless Steel

✅ Operating System: Electric - 1.25 kW

✅ Voltage: 380/220 VAC - 50 Hz

✅ Dimensions:

✔️ Length: 230 cm

✔️ Width: 90 cm

✔️ Height: 190 cm

✅ Machine Number: 002

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

💡 Why is a spiral conveyor a vital step in the production line?

✔️ Because it automatically transfers the mixture without the need for manual intervention.

✔️ Because it ensures worker safety thanks to its metal guard.

✔️ Because it maintains product quality by removing magnetic impurities.

✔️ Because it's easy to clean and drain.

✔️ Because it's ideal for continuous industrial production environments..

Double helix extruder

The heart of the forming process in the cracker production line—professional industrial performance, high flexibility, and a heavy-duty design! The extruder is the main device responsible for forming the dough for chips and crackers according to the desired shape. The dough is pressed and pushed through multiple molds to form the appropriate size and shape. This model is equipped with five different molds to form a wide range of cracker types, and its production capacity reaches 200 kg per hour, with the flexibility to change shapes upon request. This extruder is engineered to high standards to withstand continuous operation and is fully covered with a 304 food-grade stainless steel exterior for hygiene and ease of cleaning. The machine features a built-in screw feeder with a bucket for automatically feeding the dough from the screw conveyor. It includes a cutting unit mounted on the face of the extruder to precisely control the length of the cracker electronically using a variable-speed inverter.

🔧 Advanced Technical Specifications:

1️⃣ Robust Industrial Structure

✔️ The main carrier is made of heat-treated steel and equipped with strong steel support legs.

✔️ Approximate weight: 1300 kg.

2️⃣ Heavy-duty gearbox

✔️ Made of the finest metals, designed for continuous operation 24/7.

✔️ Equipped with original Swedish and Japanese SKF bearings and bearings.

3️⃣ Screw compressor motor

✔️ Power: 30 hp (22.5 kW).

✔️ Made in Italy - copper coils - heavy-gauge steel frame.

4️⃣ Advanced operating and control systems

✔️ All motors are electronically controlled via three inverters.

✔️ Grain length control is achieved via a variable-speed rotating knife.

✔️ Equipped with an electronic start-up heater.

5️⃣ Smart and independent control panel

✔️ Made of 304 food-grade stainless steel - dust-proof.

✔️ Equipped with 3 cooling fans + 3 ventilation filters – with a special ventilation system for hot areas.

✔️ Programmable, automatic fault reading, electrical diagram included.

6️⃣ Easy mobility and maintenance

✔️ The machine is equipped with sturdy wheels for easy movement within the production line.

✔️ No need to disassemble the machine to clean the coil – designed for long-term operation.

📏 Technical Specifications:

✅ Machine Type: Twin-Screw Extruder

✅ Production Capacity: 200 kg/h

✅ Number of Molds: 5 Interchangeable Shapes

✅ Slicer Type: Electronic - Variable Speed

✅ Control System: Independent External Panel - PLC - Inverter

✅ Material: Food-grade 304 Stainless Steel

✅ Electrical Voltage: 380/220 VAC - 50 Hz

✅ Electrical Power: 33.75 kW

✅ Dimensions:

✔️ Length: 250 cm

✔️ Width: 100 cm

✔️ Height: 180 cm

✅ Machine Number: 003

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

💡 Why Choose This Extruder?

✔️ Because it is the foundation of the forming process in the production line.

✔️ Because it ensures consistent quality and a variety of shapes.

✔️ Because it's designed to withstand heavy-duty, non-stop operation.

✔️ Because it features precise control technologies that ensure high efficiency.

✔️ Because it's easy to clean and safe in an industrial work environment.

Extruder face cutter

Precise control of grain length and shape – integrated with the extruder, it operates smoothly and efficiently! This cutter is mounted directly onto the face of the extruder and is used to cut the emerging chips into the pre-determined shape and length. High-precision cutting is performed using a rotating knife electronically controlled via an inverter, allowing complete flexibility in producing chips of various lengths. The cutter supports the production of more than five different chip shapes and is designed with a fully integrated 304 food-grade stainless steel body for easy cleaning and safe operation.

⚙️ Working mechanism:

1️⃣ Instant cutting at the extruder exit

✔️ The chips are cut as soon as they exit the forming die, without delay or manual intervention.

2️⃣ Electronically controlled rotating knife

✔️ The cutting speed is electronically controlled via an inverter, allowing precise grain length control.

3️⃣ Multiple Shape Production

✔️ Ability to produce more than 5 patterns by changing the mold or cutting speed.

4️⃣ Compact and Hygienic Design

✔️ The cutter is directly integrated with the extruder, reducing line size and increasing efficiency.

✔️ Made entirely of food-grade 304 stainless steel.

📏 Technical Specifications:

✅ Device Type: Integrated Slicer with Extruder Face

✅ Number of Shapes: More than 5

✅ Control System: Speed Inverter

✅ Material: Food-grade 304 stainless steel

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 2.25 kW

✔️ Length: 80 cm

✔️ Width: 100 cm

✔️ Height: 120 cm

✅ Machine Number: 004

✅ Model: THV-2025 SH-Z

✅ Country of Origin: Turkey

💡 Why is this slicer essential in the production line?

✔️ Because it allows the grain to be cut immediately after exiting the extruder.

✔️ Because it is compact and saves space in the workshop.

✔️ Because it operates with high precision thanks to electronic control.

✔️ Because it supports a variety of shapes and a professional appearance for chips.

✔️ Because it's made of safe materials and is easy to clean.

punching machine

Precise Chip Engraving – Hygienic industrial design, excellent results, and complete control of the final shape! The perforator is used in chip and cracker production lines to add fine engravings and perforations to the dough threads emerging from the extruder or cutter, giving the chips their desired final shape. The chips are passed through a special stamping cylinder that creates the patterns on the surface before they enter the cutting or drying stage, allowing for a distinctive visual diversity in the final product.

⚙️ How it works:

1️⃣ Passing the chip threads through the stamping machine

✔️ The chip threads are fed into a precisely etched metal cylinder to create the engravings and perforations according to the desired shape.

2️⃣ Production of various shapes

✔️ The machine allows for multiple designs on the chips, such as dots, lines, or raised geometric shapes.

3️⃣ Hygienic and easy-to-install design

✔️ The entire body is made of food-grade 304 stainless steel, making it ideal for working with food products.

📏 Technical Specifications:

✅ Machine Type: Chip Thread Stamping/Engraving/Perforating Machine

✅ Operation Method: Stamping cylinder with multiple shapes

✅ Material: Food-grade 304 stainless steel

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 2.25 kW

✅ Dimensions:

✔️ Length: 150 cm

✔️ Width: 100 cm

✔️ Height: 120 cm

✅ Machine Number: 005

✅ Model: THV-2025 PV

✅ Country of Origin: Turkey

💡 Why is a perforating machine a distinct choice in the production line?

✔️ Because it adds visual distinction to the grain, enhancing the product's appeal.

✔️ Because it operates with precise stamping technology without damaging the threads.

✔️ Because it is easy to integrate with extruders or cutters.

✔️ Because they're made from healthy, food-safe materials.

✔️ Because they expand your brand's design options.

steak slicer

A precise system for cutting chips in multiple shapes and adjustable lengths – fast performance, hygienic design, and intelligent electronic control! The steak cutter is a key unit in the potato chips production line, shaping the dough strands coming from the extruder and cutting them into the desired shape and length. The cutter can produce more than 10 different shapes of chips, with full flexibility in controlling the length of the strand using an electronic speed inverter, allowing for high precision in every cut. The cutter is designed to be integrated with a conveyor belt made of food-grade plastic, in addition to a dedicated pull cylinder to attract the chips and guide them toward the knife in an organized and smooth manner.

⚙️ Working mechanism:

1️⃣ Pulling dough strands from the extruder

✔️ The device contains a pull cylinder that precisely pulls the dough strands toward the knife.

2️⃣ Variable-length electronic cutting

✔️ Equipped with an electronically inverter-controlled knife to determine the desired length according to the shape.

3️⃣ Multiple Shapes Production

✔️ Ability to create more than 10 different styles of chips by easily changing the blades.

4️⃣ Hygienic and Safe Industrial Design

✔️ Made entirely of food-grade 304 stainless steel.

✔️ Conveyor belt made of food-grade, bacteria-resistant plastic.

📏 Technical Specifications:

✅ Device Type: Chips Slicer - Steel Strip

✅ Number of Shapes: More than 10

✅ Control System: Inverter Speed Variable

✅ Conveyor: Integrated food-grade plastic conveyor

✅ Material: Food-grade 304 stainless steel

✅ Voltage: 380/220VAC - 50Hz

✅ Power: 2.25 kW

✅ Dimensions:

✔️ Length: 150 cm

✔️ Width: 80 cm

✔️ Height: 120 cm

✅ Machine Number: 006

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

💡 Why is this slicer the ideal choice for your potato chips production line?

✔️ Because it ensures precise control of grain length and cutting speed.

✔️ Because it supports more than 10 easily interchangeable shapes.

✔️ Because it's integrated into a healthy and food-safe conveyor line.

✔️ Because it's designed to operate efficiently within an automated production line.

✔️ Because it's quick and easy to operate and adjust.

3D cutter

Creativity in 3D Chip Forming – High Precision, Production Flexibility, and Advanced Electronic Control! The 3D cutter is used to cut and shape the chips' dough strands into various 3D shapes. It offers the ability to produce more than 7 distinct shapes thanks to its precise knife system and electronically adjustable cutting speed. The machine is equipped with a chip strand drawing cylinder to ensure even direction toward the knives, as well as straightening fingers that prevent the strands from sticking together during movement, ensuring the final shape and smoothness of the chip.

⚙️ Working Mechanism:

1️⃣ Drawing and guiding the strands toward the cutter

✔️ A powerful drawing cylinder pulls the dough strands from the extruder and ensures even feeding.

2️⃣ Straightening the strands and preventing sticking

✔️ Equipped with internal straightening fingers that separate the strands and prevent clumping before cutting.

3️⃣ 3D Cutting

✔️ Rotating knife unit with speed-controlled inverter to produce the desired shape and length.

4️⃣ Multi-shape Production

✔️ The machine can produce more than 7 different patterns depending on the installed mold.

📏 Technical Specifications:

✅ Machine Type: 3D Slicer

✅ Number of Shapes: More than 7

✅ Operating System: Inverter - Electronic Speed Control

✅ Suction System: Chip Thread Feeding Cylinder

✅ Straightening System: Internal Thread Straightening Fingers

✅ Material: Food-grade 304 Stainless Steel

✅ Voltage: 380/220VAC - 50Hz

✅ Power: 3.75 kW

✅ Dimensions:

✔️ Length: 120 cm

✔️ Width: 100 cm

✔️ Height: 120 cm

✅ Machine Number: 007

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

💡 Why choose a 3D slicer for your production line?

✔️ Because it produces attractive and diverse 3D chip shapes.

✔️ Because they prevent thread sticking, ensuring quality and shape stability.

✔️ Because they are equipped with electronic control systems to adjust speed and accuracy.

✔️ Because they are designed to efficiently handle continuous industrial production.

✔️ Because they are easy to clean and have a long operating life.

Product conveyor belt

Smooth and safe product transfer after baking – Durable design, easy movement, and high hygienic quality. This conveyor belt is used to transport finished product after it exits the oven to the next stages of the production line, such as seasoning or packaging. Equipped with sturdy wheels for easy movement in the industrial workshop, its structure is made of 304 food-grade stainless steel, making it suitable for direct use in food production lines. The conveyor is designed at a suitable angle to ensure smooth, slip-free product movement, making it suitable for continuous operation in high-performance industrial environments.

⚙️ Working mechanism:

1️⃣ Product pickup from the oven

✔️ The conveyor starts directly from the oven exit and flexibly transports the product to the next stage.

2️⃣ Easy movement and cleaning

✔️ Equipped with industrial wheels for easy movement within the production line when needed.

✔️ Its open design allows for easy cleaning.

3️⃣ Hygienic and Durable Structure

✔️ The conveyor is made of 304 food-grade stainless steel, corrosion-resistant and suitable for direct contact with food.

📏 Technical Specifications:

✅ Device Type: Oven Conveyor

✅ Drive System: Industrial Wheels

✅ Conveyor Material: 304 food-grade stainless steel

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 3.75 kW

✅ Dimensions:

✔️ Length: 300 cm

✔️ Width: 70 cm

✔️ Height: 190 cm

✅ Machine Number: 008

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

💡 Why is this conveyor belt an important step in the production line?

✔️ Because it smoothly transports hot product without damage or friction.

✔️ Because it provides flexibility in the lab's interior layout thanks to its cabinets.

✔️ Because it's made from safe, food-grade materials.

✔️ Because it's easy to operate, clean, and maintain.

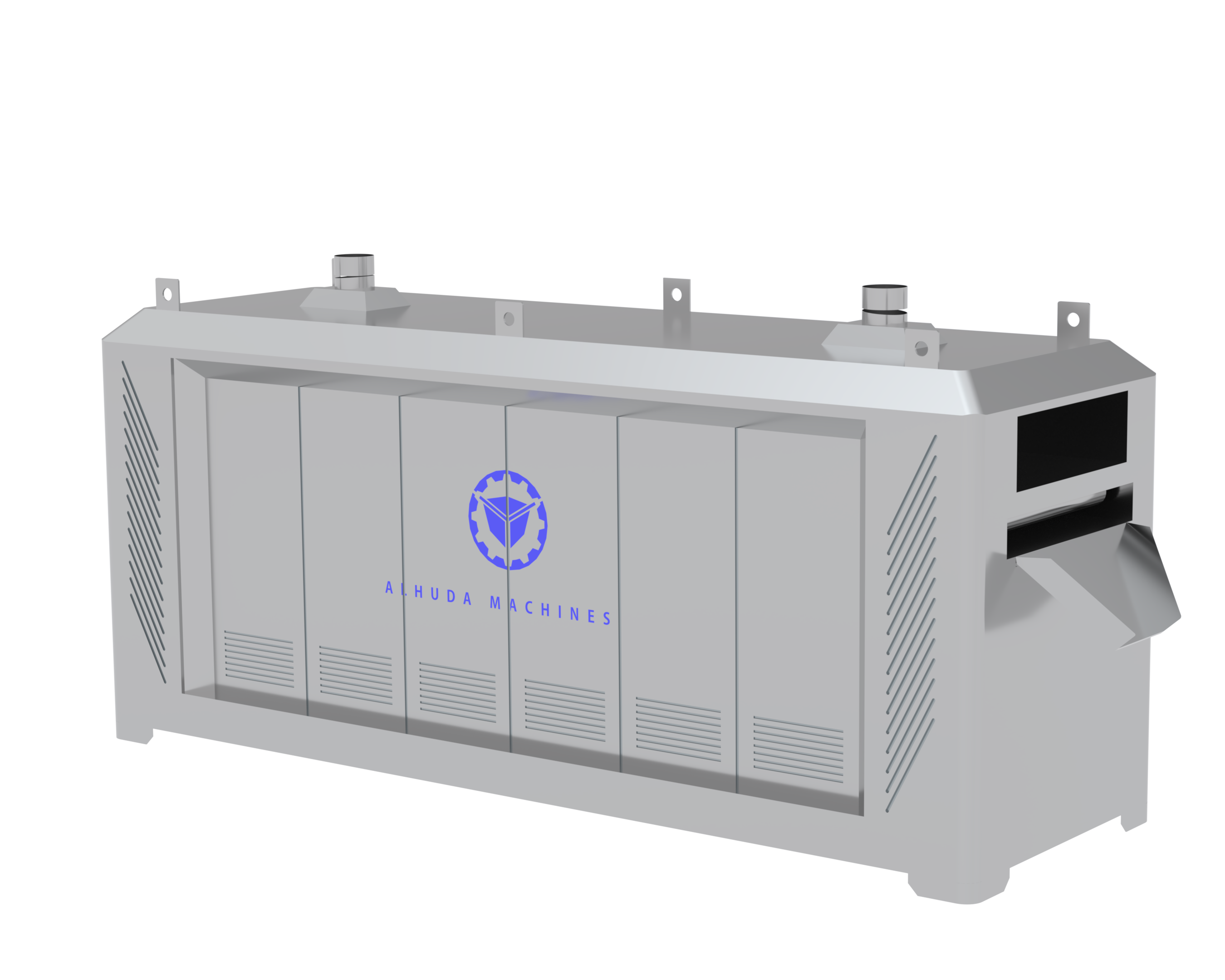

Hot air grill oven

American technology for drying and roasting chips – high production capacity, precise control, and an ideal industrial design for continuous operation! This oven is one of the most important components of the chips production line, drying and roasting chips using a highly efficient hot air system. Developed using American Extrusion technology, this model has a production capacity of up to 400 kg/hour and an operating temperature of up to 300°C. The system allows the final moisture content of the product to be adjusted from 0% to 5% as required, and operates on diesel or natural gas (LPG) as desired.

⚙️ Working mechanism and operating details:

1️⃣ Durable and hygienic industrial structure

✔️ Made entirely of food-grade 304 stainless steel.

✔️ Oven length: 7 meters – Frame width: 1.5 meters – Conveyor width: 1 meter

✔️ Internal carrying grill made of 304 stainless steel.

2️⃣ Strong and removable heating chamber

✔️ Made of chrome and treated steel to withstand temperatures up to 800°C.

✔️ Equipped with an Italian burner (Riello or Baltur) model 2023.

3️⃣ Integrated heating and air distribution system

✔️ Equipped with a hot air distribution mechanism from the top and bottom with lateral circulation.

✔️ Two fans (pump and extract) with a capacity of 3 hp each – excellent Italian or Turkish manufacture.

4️⃣ Highly efficient thermal insulation

✔️ Internal insulation made of fiberglass, 12 cm thick on all sides.

5️⃣ Advanced control systems

✔️ Independent, removable control panel made of food-grade stainless steel.

✔️ Equipped with a touch screen – electronic fault reading system via text messages.

✔️ Belt and fan speed control via inverter (LS brand).

✔️ All electrical components are SCHNEIDER (France) and LS (Korea).

6️⃣ Automatic Cleaning System

✔️ Equipped with an automatic cleaning mechanism for the conveyor mesh carrying the chips.

📏 Technical Specifications:

✅ Device Type: Hot Air Drying and Roasting Oven

✅ Production Capacity: 400 kg/h

✅ Temperature: Up to 300°C

✅ Final Humidity: 0% to 5%

✅ Fuel Type: Diesel or Natural Gas (LPG)

✅ Number of Heating Hours: 2 – Programmable

✅ Operating System: Touch Screen + Inverter + Independent External Panel

✅ Material: Food Grade 304 Stainless Steel

✅ Electrical Voltage: 380/220 VAC – 50 Hz

✅ Electrical Power: 10.5 kW

✅ Dimensions:

✔️ Length: 700 cm

✔️ Width: 130 cm

✔️ Height: 220 cm

✅ Machine Number: 009

✅ Model: THV-2025 PV-B

✅ Country of Origin: Turkey

💡 Why This Oven Is Considered Your ideal choice?

✔️ Because it dries and roasts the product precisely and provides optimal humidity control.

✔️ Because it is equipped with advanced American technology and a robust industrial structure.

✔️ Because it features intelligent, environmentally friendly control systems.

✔️ Because it is easy to clean and maintain thanks to its practical design.

✔️ Because it is suitable for continuous production in large factories.

Product conveyor line

Clean and efficient product transfer from cutter to oven – hygienic design, easy movement, and reliable performance! This conveyor belt is used to transport potato chips directly from the cutter to the roasting or drying oven, ensuring smooth product flow without damage or clumping. The conveyor features a robust frame made of food-grade 304 stainless steel and a food-grade PVC belt that is resistant to bacteria and moisture. It is equipped with heavy-duty industrial casters for easy movement within the workshop or factory, allowing flexibility in production line layouts and easy cleaning after use.

⚙️ How it works:

1️⃣ Receiving the product from the cutter

✔️ The conveyor starts at the end of the cutter and transports the chips to the oven at a carefully designed angle.

2️⃣ Hygienic and safe transport

✔️ The belt is made of food-grade PVC, ensuring product safety during transport.

3️⃣ Easy movement and cleaning

✔️ Equipped with industrial casters for easy movement.

✔️ Its open design ensures quick and easy cleaning.

📏 Technical Specifications:

✅ Machine type: Food-grade plastic conveyor belt

✅ Function: Transport from cutter to oven

✅ Belt material: Food-grade PVC

✅ Frame material: Food-grade 304 stainless steel

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 1.25 kW

✅ Dimensions:

✔️ Length: 200 cm

✔️ Width: 70 cm

✔️ Height: 160 cm

✅ Machine number: 010

✅ Model: THV-2025 PV-B

✅ Country of origin: Turkey

💡 Why do you need this conveyor belt in your production line?

✔️ It transports the product smoothly without damaging it or causing it to clump together.

✔️ It is easy to clean and move around the production area.

✔️ It is made of hygienic, food-safe materials.

✔️ It efficiently completes the process between slicing and baking.

Flavor cooking mixers

Perfect harmony between oil and flavor – hygienic industrial design, indirect heating, and an integrated mixing system! Flavor cooking mixers are an essential part of the chips and crackers production line, combining oil with flavor to create a homogeneous mixture that is later used in the seasoning process. Each mixer has a capacity of approximately 200 liters and is designed with double jacket indirect heating technology, ensuring the quality of the ingredients and preventing burning. The mixers are mounted on a unified chassis with a distribution pump. They are made of heat-coated iron and fully covered with 304 food-grade stainless steel. They are equipped with industrial wheels for easy movement and cleaning.

⚙️ How it works:

1️⃣ Mixing oil with flavor

✔️ The oil and flavor are introduced into the mixer to be thermally combined until a completely homogeneous mixture is achieved.

2️⃣ Safe Indirect Heating

✔️ The mixer is equipped with a double jacket filled with hot water to ensure smooth and safe heating without direct contact.

3️⃣ Precise Monitoring and Control

✔️ Equipped with a thermometer to measure the temperature of the hot water.

✔️ Equipped with a level indicator to indicate the amount of water inside the jacket.

4️⃣ Unified Chassis with Pump

✔️ All mixer and pump components are mounted on a single, solid base for easy installation and movement.

📏 Technical Specifications:

✅ Appliance Type: Flavored Cooking Mixer - Indirect Heating System

✅ Blender Capacity: 200 Liters (Approximately)

✅ Heating Type: Double Jacket - Hot Water

✅ Material: 304 Food Grade Stainless Steel

✅ Base: Painted Iron Chassis with Stainless Steel Cover

✅ Drive System: Industrial Wheels

✅ Voltage: 380/220VAC - 50Hz

✅ Power: 3.75 kW

✅ Dimensions:

✔️ Length: 300 cm

✔️ Width: 70 cm

✔️ Height: 100 cm

✅ Machine Number: 011

✅ Model: THV-2025TA-F

✅ Country of Origin: Turkey

💡 Why Choose These Flavored Cooking Mixers?

✔️ Because they ensure perfect flavor and oil balance.

✔️ Because they're safe and easy to operate thanks to indirect heating.

✔️ Because they're designed to suit sanitary industrial environments.

✔️ Because they're easy to move and clean, saving time and effort.

✔️ Because they're an indispensable part of every professional glazing line.

Flavor Pump

Precise Flavor Dispensing with Maximum Efficiency – American technology, electronic control, and a durable industrial design! The flavor pump is used to pump the oil and flavor mixture from the mixers to the flavor spray cylinder. It features alternating pumping technology that ensures optimal flavor consumption without waste. The body is made of solid European aluminum, and the pump is mounted on a platform equipped with wheels for easy movement and cleaning. The pump is powered by a powerful industrial Ankernage motor, connected to the pump body via flexible rubber cables for easy disassembly and maintenance. It is also equipped with a high-quality, food-grade silicone hose made in Spain. The flavor quantity is precisely controlled electronically using an inverter, allowing for complete control of the flavor flow depending on the product type.

⚙️ How it Works:

1️⃣ Alternating pumping system (suction + pumping)

✔️ The operating system relies on American technology to reduce waste and achieve high efficiency in flavor dispensing.

2️⃣ Industrial Ankernage Motor

✔️ Connected to the pump via rubber cables for easy maintenance.

3️⃣ Precise Electronic Control

✔️ Equipped with an inverter that allows the flavor quantity to be adjusted as needed.

4️⃣ Product Safety and Hygiene

✔️ The hose used for transportation is made of food-grade silicone – made in Spain.

✔️ All parts in contact with the product are made of 304 food-grade stainless steel.

📏 Technical Specifications:

✅ Device Type: Flavor Pump – Alternating Pumping System

✅ Pumping System: Suction and Pump (Alternating) – American Technology

✅ Operating System: Electronic – Inverter for Quantity Control

✅ Material: Solid European Aluminum + 304 food-grade stainless steel

✅ Hose: Food-grade silicone – Made in Spain

✅ Movement System: Platform with Wheels

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 1.25 kW

✅ Dimensions:

✔️ Length: 70 cm

✔️ Width: 60 cm

✔️ Height: 80 cm

✅ Machine Number: 012

✅ Model: THV-2025TA-F

✅ Country of Origin: Turkey

💡 Why is this flavor pump a professional choice?

✔️ Because it efficiently delivers flavor without waste.

✔️ Because it's easy to clean and maintain thanks to its flexible coupling design.

✔️ Because it's equipped with precise electronic control.

✔️ Because it's designed with high-quality food-grade materials.

✔️ Because it's lightweight and easy to move around the lab.

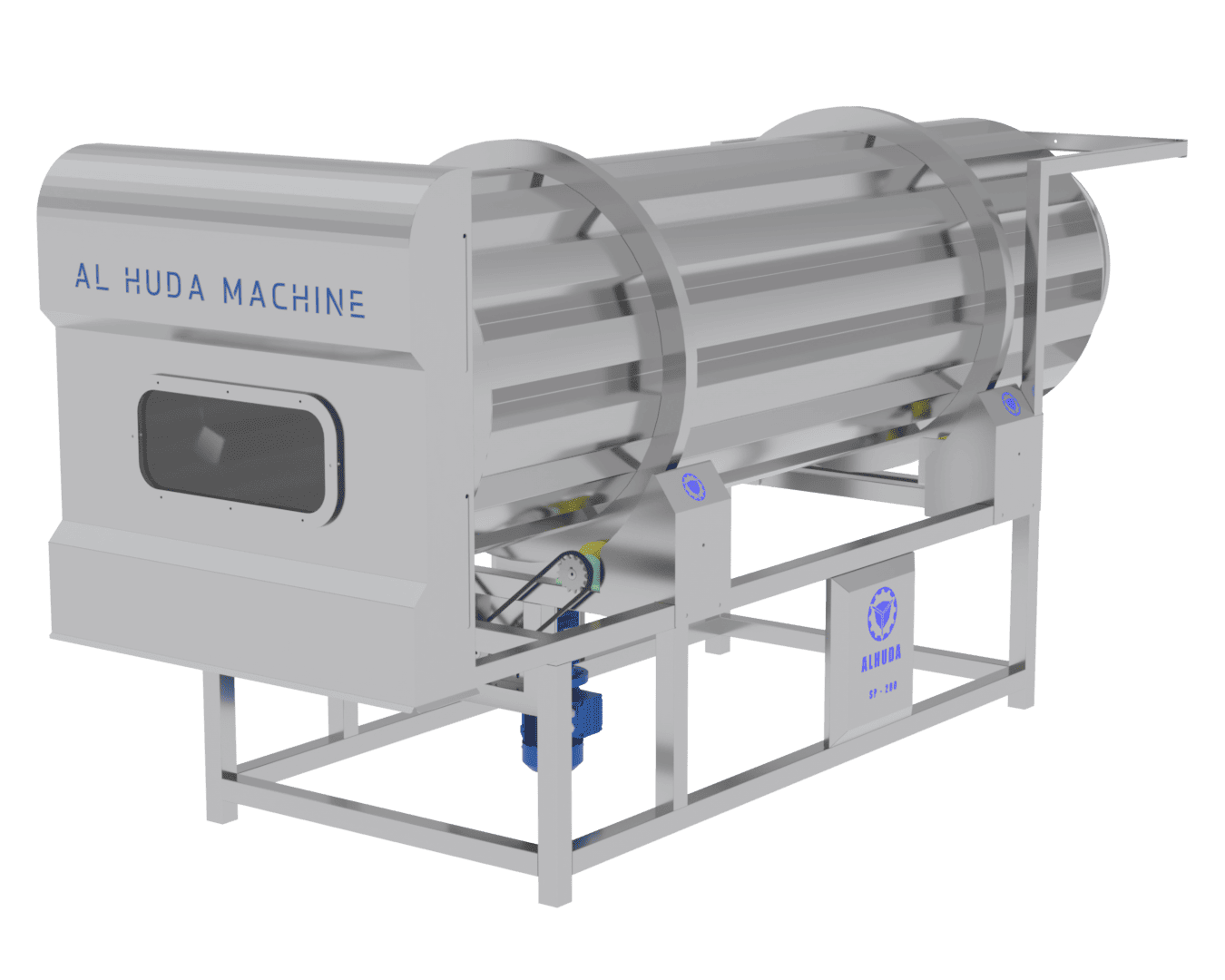

Flavor coating cylinder

Perfect flavoring for chips with a fine mist – hygienic design, electronic control, and unparalleled flavoring quality! The seasoner is a specially designed cylindrical unit for professionally and evenly spraying flavor onto chips. The drum's rotation speed is electronically controlled by an inverter, allowing precise adjustment of the flavoring time inside the seasoner. The device is equipped with an advanced American-style flavor sprayer that can be calibrated according to the desired flavor amount. The drum's internal scales are engineered to prevent clumping or flavor accumulation in specific areas, facilitating slow, even rotation of the chips.

⚙️ How it works:

1️⃣ High-precision flavor spraying

✔️ Equipped with an advanced American-style flavor sprayer that can be calibrated for optimal coverage.

2️⃣ Slow, even rotation of the chips

✔️ The drum rotates slowly to ensure light friction and even flavor distribution across the entire surface of the chip.

3️⃣ Electronic Speed and Time Control

✔️ Equipped with an inverter to control the rotation speed and the time the chips pass through the seasoning.

4️⃣ Automatic Impurity Ejection

✔️ Includes a mechanism to eject small grains and unwanted impurities to ensure the quality of the final product.

5️⃣ Hygienic and Easy-to-Move Design

✔️ Made of food-grade 304 stainless steel.

✔️ Equipped with a chrome cover at the material exit area.

✔️ Equipped with industrial wheels for easy transportation and cleaning.

📏 Technical Specifications:

✅ Device Type: Flavoring Cylinder (Marinator)

✅ Spray System: American Flavoring Spray - Adjustable

✅ Control: Inverter to adjust rotation speed and passage time

✅ Particle Discharge: Automatic Internal Discharge Mechanism

✅ Material: Food-grade 304 stainless steel + chrome cover

✅ Drive System: Industrial wheels

✅ Voltage: 380/220VAC - 50Hz

✅ Power: 3.75 kW

✅ Dimensions:

✔️ Length: 300 cm

✔️ Width: 120 cm

✔️ Height: 150 cm

✅ Machine Number: 013

✅ Model: THV-2025PV-B

✅ Country of Origin: Turkey

💡 Why is the seasoning an essential component of the production line?

✔️ Because it ensures perfect coating of the chips with flavor.

✔️ Because it prevents clumping and gives you a homogeneous product.

✔️ Because it automatically expels impurities.

✔️ Because it is calibrated and adjustable according to the type of flavor or product.

✔️ Because it is easy to stir and clean and suitable for intensive industrial environments.

Packing machine feeder conveyor line

Precise and balanced conveying to maintain product quality. The conveyor belt is one of the most important stages of potato chips production, ensuring efficient product transfer from the flavoring stage to three packaging machines, while preserving the integrity of the chips through a fully automated and precise distribution system. Advanced Operation Mechanism

1️⃣ Precise electronic control system. The product transfer speed is controlled by an electronic control circuit equipped with modern sensors, allowing for balanced product feeding according to the capacity of the packaging machines.

✅ Equipped with a reservoir and vibrator to ensure a consistent flow of chips without accumulation or jamming.

✅ Fully automated to reduce manual intervention and increase production efficiency.

2️⃣ Conveyor belt with an advanced design equipped with a Z-shaped PVC belt to facilitate product transfer at an appropriate angle, helping achieve optimal flow without affecting the shape of the chips.

✅ Made of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Its design reduces vibration and shock, keeping the product unbroken.

3️⃣ Smart sensors for improved performance. Advanced electronic sensors automatically adjust product speed and flow, preventing any buildup or congestion in the production line.

✅ Ensures even product distribution between packaging machines for stable and consistent production.

4️⃣ Durable and easy-to-clean design. Made entirely of food-grade 304 stainless steel to ensure rust resistance and easy cleaning, with a robust structure to withstand continuous operation in industrial environments.

✅ Equipped with sturdy wheels for easy movement and maintenance. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest levels of hygiene and quality.

✅ Electrical Power: 5.25 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 10 cm

Width: 90 cm

Height: 380 cm

✅ Machine Number: 014

✅ Model: THV-2025PV-B

✅ Country of Manufacture: Turkey Conveyor Line Features

✔️ Precise electronic control system with sensors to automatically adjust the product conveying speed.

✔️ Z-shaped PVC conveyor ensures optimal flow without compromising the quality of the slices.

✔️ Shock and vibration-resistant design to protect the product from breakage.

✔️ Tank and vibrator to ensure consistent flow and prevent product accumulation during conveying.

✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning.

✔️ Equipped with sturdy wheels for easy movement and cleaning, making it ideal for industrial environments.

💡 The ideal solution for efficient product transfer and ensuring the highest levels of production quality!

Continuous system weight packaging machines No.3

Accurate and fast food packaging with advanced systems. The weight packaging machine is designed according to the latest global technologies to ensure high speed, 24-hour operation, and superior weight and packaging accuracy. It features advanced drive systems, precise optical sensors, and an integrated electronic control system that ensures high efficiency and consistent production. Advanced Operation Mechanism:

1️⃣ Precise and flexible packaging system. Automatic packaging of potato chips, chips, seeds, and nuts. It relies on an intelligent weighing system to ensure packaging accuracy and reduce waste.

2️⃣ Advanced electronic control for smooth operations. Advanced PLC system from Delta for fast response and precise control. 7-inch electronic touch screen from Delta for ease of operation. Precise OMRON thermal control system allows temperature adjustment from the screen to ensure weld quality.

3️⃣ High performance with powerful motors and gearboxes to control the conveyor belt and jaws, ensuring stable operation. Stepper motor for automatic roll-carrying movement controlled via the screen. A stepper motor compensates for roll pull and an alarm system when the roll is finished.

4️⃣ Safe and durable design. Safety sensors protect the operator from any operational errors. A comprehensive daily production counter for performance monitoring and effective production tracking. The entire body is made of 304 food-grade stainless steel to ensure hygiene and product safety. All parts in contact with the product are made of 304 stainless steel in compliance with food quality standards.

5️⃣ Flexible roll usage. Roll width can be customized to suit customer requirements, allowing for the packaging of a variety of products. Maximum roll length: 320 mm. An Italian-made roll forming device is easy to replace to increase operational efficiency. Supports the use of an integrated cellophane roll to ensure tight, high-quality packaging.

6️⃣ Additional equipment to increase efficiency: A Z-shaped PVC conveyor belt with a 304 stainless steel structure and an automatic feeding system. A conveyor belt for finished packages to ensure easy transportation and storage. A date printer to print product information directly onto the package. A smart weighing system from HIGH DREAM to ensure high weight accuracy. The weighing platform is made of 304 stainless steel to ensure stability and reliability. Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to maintain hygiene and quality.

✅ Power: 5.75 kW | 380/220 V | 50 Hz.

✅ Dimensions: Length: 200 cm

Width: 130 cm

Height: 420 cm

🔢 Machine Number: 015

✅ Model: THV-2025 PV-B

✅ Country of Origin: Turkey. Robust design to ensure high performance:

✔ High weight accuracy via the smart summation system.

✔ Comprehensive electronic control for maximum operational efficiency.

✔ Integrated safety with safety sensors to protect the operator.

✔ Flexibility in using packaging rolls according to customer needs.

✔️ High-quality European components ensure machine durability. Features of the weight packaging machine:

✔️ High speed and high packaging accuracy.

✔️ Advanced PLC electronic control system enables smooth and responsive operation.

✔️ Durable 304 stainless steel construction materials ensure cleanliness and product safety.

✔️ Practical and easy-to-maintain design to extend machine life.

✔️ Integrated safety systems to ensure operator safety.

💡 The ideal solution for filling and packaging food products with extreme efficiency and precision.

Control Panel

• SCHNEIDER breakers

• SCHNEIDER contactors

• 10-inch DELTA control screen

• DELTA inverters

• GAMAK motors with German license

• YILMAZ gearboxes

basic information

🏭 The Tarabish Crispy Chips Production Line is 100% healthy - oil-free - made in Turkey with German technology. We present to you the Tarabish Chips Production Line, made from corn flour and wheat flour, with carefully considered ingredients such as calcium, carbonates, and sugar, to produce a light and delicious product. It is cooked with hot air inside the oven without the use of any oils, making it a healthy and suitable choice for lovers of light and crunchy foods.

⚙️ Production Line Specifications:

🔸 Line Length: 35 meters

🔸 Line Width: 3 meters

🔸 Required Area: 300 square meters

🔸 Production: More than 30 different types of chips

🔸 Turkish-made, with German technology spanning over 20 years

🎖️ Quality and Warranty: Our lines have international quality certifications. Al-Huda Company bears full responsibility for the specifications and quality of the line. The line is tested on-site at Al-Huda Company. If the line doesn't meet the customer's needs, we guarantee a full refund. 🤝 Trust that Transcends Generations: Al-Huda has generations of experience in the world of industry, combining the quality of the past with the creativity of the present. We develop today to lead the future.

📩 Contact Us: Feel free to ask any questions or request modifications. We are happy to provide you with all the details and information. Al-Huda... Your Best Choice

Gallery