Cheetos chips production line with frying system, production capacity 200 kg

🔸 Cheetos Chips Production Line – Oil-Frying System A specialized industrial line for producing Cheetos-style chips using an oil-frying system.

It features easy operation and control, and includes automated, continuous processes for mixing, extruding, frying, seasoning, and packaging.

Made entirely of food-grade stainless steel with high-quality construction, ensuring stable performance and a long service life.

The line consists of the following parts:

1_Corn mixer

2_Spiral conveyor

3_Extruder

4_Product conveyor belt

5_Sieve

6_Fryer

7_Two oil tanks

8_Oil type shaker

9_Cooling conveyor line

10_Spice rinsing device

11_Spiced flavor coating cylinder

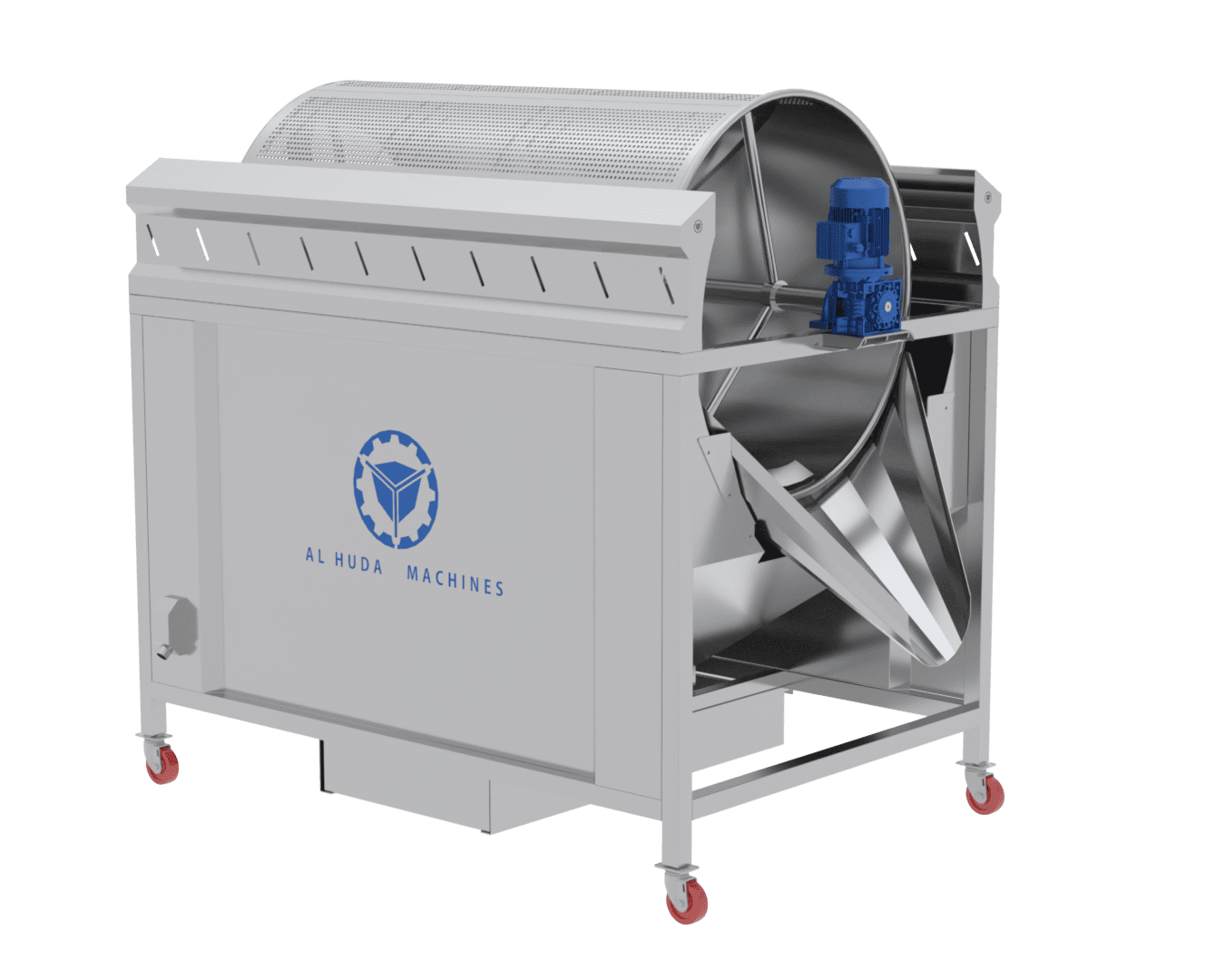

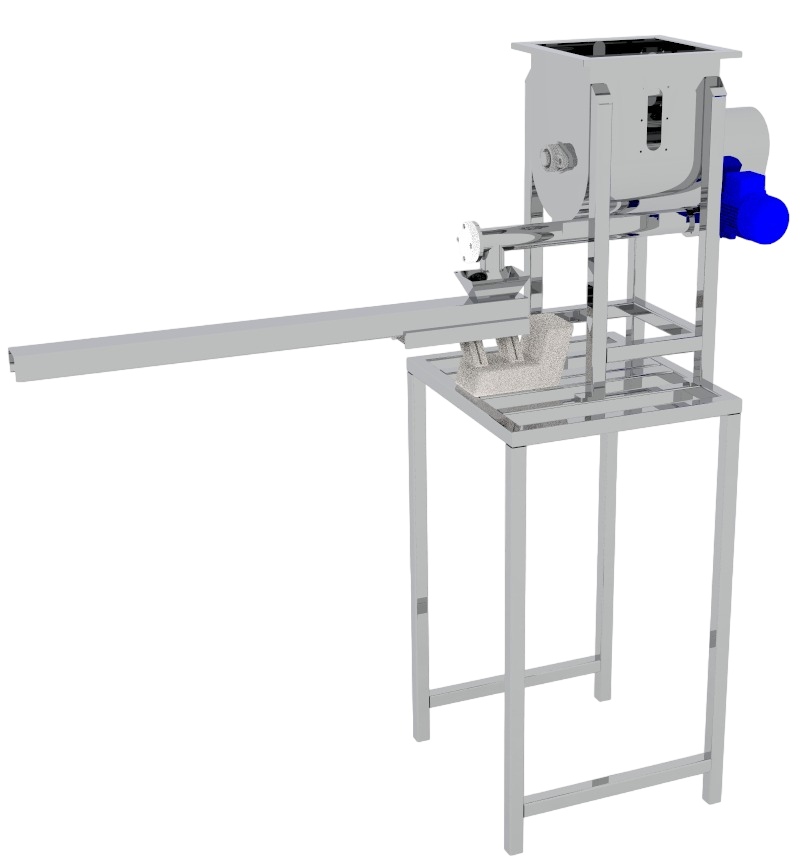

corn mixer

Homogeneous and precise mixing of corn to the highest quality standards. The corn mixer is an essential piece of equipment for preparing corn before the manufacturing process. It achieves perfect homogeneity in the corn mixture by adding the precise moisture content, ensuring even distribution and professional preparation of the final product. Advanced Operation Mechanism

1️⃣ Large capacity and high-quality manufacturing materials. Capacity: 400 kg, allowing for efficient processing of large quantities of corn. Material: Made entirely of 2 mm thick food-grade 304 stainless steel, ensuring rust resistance and maintaining product hygiene.

2️⃣ Powerful motor to ensure perfect mixing. Main motor: 5 HP, Turkish-made, ensuring stable performance and high mixing efficiency. A homogeneous mixing mechanism ensures optimal distribution of ingredients within the mixer.

3️⃣ Precise moisture control. Equipped with a built-in water tank, it allows for precise control of the corn moisture content to achieve the desired consistency. A water level indicator helps accurately adjust the quantity during the mixing process.

4️⃣ A high-security worker safety system equipped with mechanical protection (metal mesh) that prevents workers from entering the mixer during operation, ensuring a safe working environment.

5️⃣ A smooth unloading and process control system equipped with a standard unloading port that allows easy product removal without clumping or loss of raw materials. Equipped with a monitoring and cleaning port, this allows for monitoring the mixing process and ensuring the cleanliness of the mixer after each use.

6️⃣ Effective removal of metal impurities: The mixer basin contains a powerful magnet that removes any metal impurities from the corn, ensuring the purity of the final product and preventing unwanted materials from entering subsequent production lines. Technical Specifications: ✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Electrical Power: 3.75 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 180 cm

Width: 120 cm

Height: 230 cm

✅ Machine Number: 001

✅ Model: THV-2025PV-Z

✅ Country of Manufacture: Turkey – High-quality manufacturing according to European standards. Durable construction and high-efficiency performance.

✔️ 2 mm thick interior design for corrosion resistance and long-lasting durability.

✔️ Smooth discharge system allows easy control of the corn extraction process after mixing.

✔️ High mechanical protection to ensure worker safety during operation.

✔️ Magnets inside the tub to remove any metal impurities that may affect product quality.

✔️ Precise control of corn moisture through a built-in water tank and level indicator.

✔️ Robust and durable design made entirely of food-grade 304 stainless steel to ensure maximum hygiene.

✔️ High-security system with a metal mesh to prevent hand entry during operation.

✔️ Effective removal of metal impurities using the built-in magnet in the tub.

✔️ Easy emptying and cleaning via dedicated holes.

✔️ High-performance motor to ensure optimal mixing efficiency and highest quality.

💡 The perfect solution to ensure homogeneous mixing and professional preparation of corn with the best quality and operational efficiency!

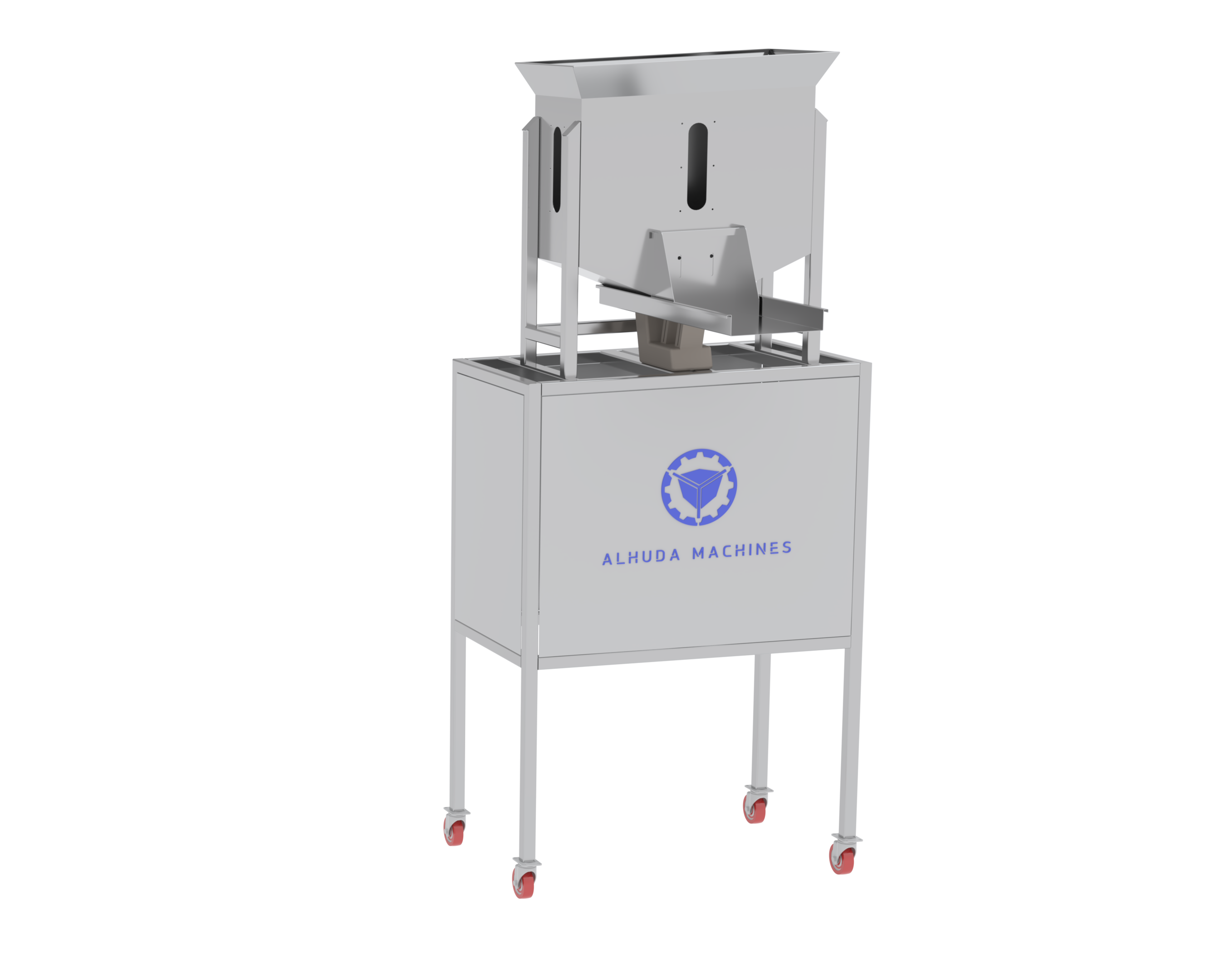

screw conveyor

Precise, efficient, and safe automated material conveying. The spiral conveyor is one of the most important pieces of equipment in production lines. It automatically feeds materials into the extruder in a smooth and efficient manner, ensuring a consistent flow and improving production efficiency with the highest levels of safety and quality. Advanced working mechanism

1️⃣ A spacious tank made of high-quality materials. Capacity: 75 kg, allowing sufficient storage of materials to ensure continuous production without interruption. Material: Made entirely of 2 mm thick food-grade 304 stainless steel, providing high rust resistance and ensuring product hygiene.

2️⃣ Automatic extruder feeding to ensure consistent flow. The conveyor automatically feeds materials into the extruder, reducing the need for manual intervention and ensuring efficient work continuity. A precise spiral design ensures smooth material transfer without clumping or interrupting flow.

3️⃣ A high-security worker safety system equipped with a metal mesh as mechanical protection to prevent the operator's hand from entering the conveyor during operation, providing a safe working environment.

4️⃣ Efficient removal of metal impurities. Equipped with an advanced magnetic mechanism that removes any metal impurities that may be present within the materials, preserving the quality of the final product and protecting the machines from damage.

5️⃣ Easy cleaning and maintenance. Equipped with a dedicated bottom opening for cleaning, facilitating periodic maintenance and removing any material residue inside the tank. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Power: 1.25 kW | 380/220 V | 50 Hz.

✅ Dimensions:

Length: 300 cm

Width: 90 cm

Height: 250 cm

✅ Machine Number: 002

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey - High-quality manufacturing according to European standards. Robust design and high operating efficiency.

✔ 2 mm thick internal structure for corrosion resistance and long-lasting durability.

✔️ Precise spiral design for uniform material transfer without clumping.

✔️ Easy discharge system via the bottom opening, facilitating maintenance and cleaning.

✔️ High mechanical protection to ensure worker safety during operation.

✔️ Effective removal of metal impurities using the built-in magnet.

✔️ Automatic extruder feeding to ensure consistent flow and improve production efficiency.

✔️ Durable construction made of food-grade 304 stainless steel to maintain hygiene and quality.

✔️ Integrated safety system with metal mesh to prevent accidents during operation.

✔️ Efficient removal of metal impurities using a built-in magnetic system.

✔️ Easy maintenance and cleaning thanks to the dedicated bottom opening.

✔️ Energy-saving design with low power consumption.

💡 The ideal solution for precise and safe material transfer, while achieving the highest standards of quality and operational efficiency!

Extruder

Advanced Extrusion Technology – High Production Capacity, Continuity, and Maximum Manufacturing Efficiency! This extruder is designed to operate continuously up to 24 hours a day, using the finest materials to ensure superior performance and reliability. It is the ideal choice for producing puffed corn and various snack kernels in a variety of shapes and consistent quality.

⚙️ Advanced Operation Mechanism:

1️⃣ High Production Capacity

✔️ Production capacity up to 200 kg per hour (depending on the desired kernel shape).

✔️ Equipped with a main feed screw to ensure continuous, accurate, and organized feeding of the line.

2️⃣ Robust, High-Quality Engineering Design

✔️ The main stand is made of steel heat-coated using the latest ovens to withstand various environmental factors.

✔️ The legs are made of standard steel to ensure the stability and durability of the extruder during operation.

3️⃣ Fully Insulated and Resistant Structure

✔️ Fully insulated with a 304 food-grade stainless steel outer layer to ensure cleanliness and easy maintenance.

✔️ The control panel is separate from the chassis and equipped with three ventilation filters and three cooling fans to protect the electronic components.

4️⃣ Professional Gearbox

✔️ Made of the finest metals, it can withstand long working hours.

✔️ The gearbox is specially designed for continuous, non-stop operation, with high efficiency and stable performance.

5️⃣ Heat-Treated Screws

✔️ All screws are made of the finest metals and treated with the latest vacuum furnace technology to increase operating life and corrosion resistance.

6️⃣ Powerful Motors with Fully Electronic Control

✔️ 37 kW compressor screw motor with original copper windings.

✔️ The motor body is made of highly durable galvanized steel.

✔️ All motors are speed-controlled by three electronic inverters to ensure flexible operation and energy savings.

7️⃣ Smart Start-Up Heater

✔️ Equipped with an electronic heater to ensure easy initial start-up and a thermometer for precise temperature control.

8️⃣ Smart and Advanced Control Panel

✔️ The main control panel is made of 304 food-grade stainless steel with a special ventilation system that is dust- and heat-resistant.

✔️ Equipped with a programming system for automatic fault reading and self-storage of operational data.

✔️ Includes a fully detailed electrical diagram to support easy maintenance and periodic inspection.

📏 Technical Specifications:

✅ Electrical Power: 380/220VAC – 50Hz – 39.75 kW

▫️ Length: 200 cm

▫️ Width: 100 cm

▫️ Height: 200 cm

✅ Approximate Weight: 1300 kg

✅ Machine Number: 003

✅ Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High industrial quality according to European standards. Robust construction and highly efficient performance.

💡 Why choose the THV-2025 SH-Z extruder?

✔️ High production capacity with flexible grain shapes.

✔️ Robust design to ensure 24/7 operation.

✔️ Fully insulated and durable structure, easy to clean and maintain.

✔️ Smart control panel for instant fault reading and complete control.

✔️ Powerful motors with advanced electronic control to save energy and increase performance.

🔹 The ideal choice for producing world-class quality puffed corn and snacks with professional performance!

Chips conveyor line

Advanced technology for efficient product transfer, with an intelligent engineering design to ensure cleanliness and easy maintenance! This conveyor smoothly transfers product from the extruder to the screen and features a fully food-grade design that ensures food quality and safety.

➤ How it Works:

1. ✅ Fully food-grade manufacturing: The conveyor is made of food-grade 304 stainless steel, resistant to rust and corrosion.

2. ✅ Food-grade conveyor belt: Equipped with a conveyor belt made of high-quality PVC or food-grade plastic, specially designed to safely transport food.

3. ✅ Easy to Clean: Equipped with practical cleaning nozzles and automatic cleaning brushes to ensure continuous cleaning without the need for long downtime.

4. ✅ Flexible Movement: The conveyor is equipped with sturdy wheels for easy movement and cleaning as needed.

➤ Technical Specifications: Electrical Power: 1.25 kW – 380/220 VAC – 50 Hz

Length: 300 cm

Width: 80 cm

Height: 300 cm

Machine Number: 004

Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High industrial quality according to European standards. Durable structure and highly efficient performance.

➤ Why choose this conveyor? 100% hygienic design that meets international food standards.

Easy maintenance and cleaning for increased efficiency and reduced downtime.

Smooth, reliable movement ensures uninterrupted production flow.

European manufacturing quality ensures long-lasting performance and a long service life.

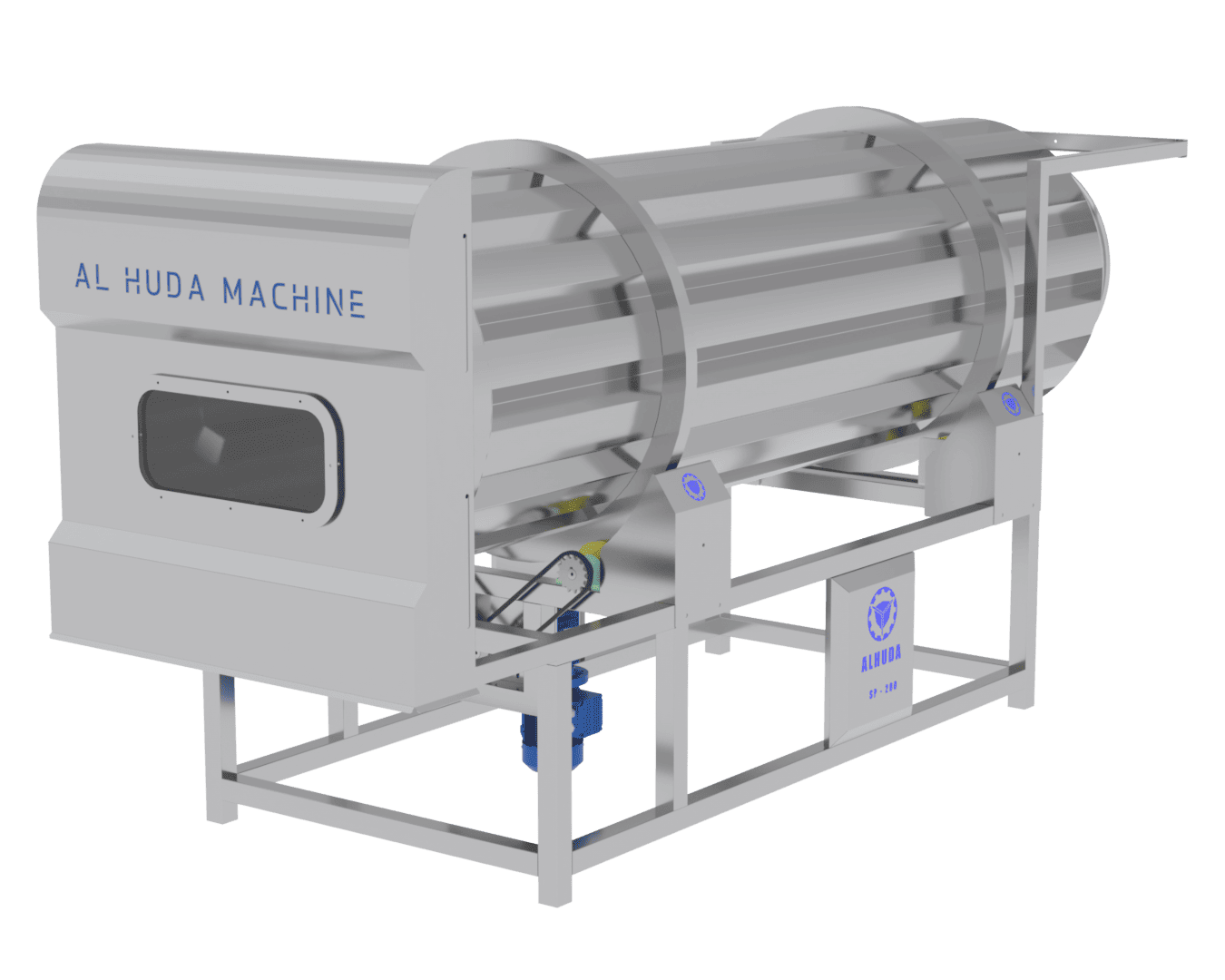

The sieve

Precise technology for product purification and removal of unwanted particles with complete efficiency and high quality! The screen is used to separate unwanted fluff and small pieces from chips through a carefully designed perforated cylinder to ensure optimal performance and final product quality.

➤ How it works:

1. ✅ Perforated cylinder design: Allows small unwanted pieces to pass through the screen's precisely designed holes.

2. ✅ Waste collection: Fluff and small crumbs are collected in a dedicated tank located below the screen and supported by a sturdy frame.

3. ✅ Automatic speed control: The screen rotates at a proportional speed that is automatically adjusted to ensure optimal sorting results.

4. ✅ Hygienic food manufacturing: All screen parts are made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and food safety.

➤ Technical Specifications:

Electrical Power: 3.75 kW – 380/220 VAC – 50 Hz

Length: 200 cm

Width: 90 cm

Height: 270 cm

Machine Number: 005

Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High industrial quality according to European standards. Durable construction and highly efficient performance.

➤ Why choose this sieve? High precision in sifting chips, resulting in a clean, impurity-free final product.

Complete food processing ensures product safety.

Easy operation and control thanks to the automatic speed control system.

High-quality Turkish products according to European specifications ensure reliable performance and long service life.

Product conveyor belt

Advanced technology for efficient product transfer, with an intelligent engineering design to ensure cleanliness and easy maintenance! This conveyor smoothly transfers product from the sieve to the fryer and features a fully food-grade design that ensures food quality and safety.

➤ How it Works:

1. ✅ Fully food-grade manufacturing: The conveyor is made of food-grade 304 stainless steel, resistant to rust and corrosion.

2. ✅ Food conveyor belt: Equipped with a conveyor belt made of high-quality PVC or food-grade plastic, specially designed to safely transfer food.

3. ✅ Easy to clean: Equipped with practical cleaning nozzles and automatic cleaning brushes to ensure continuous cleaning without the need for long downtime.

4. ✅ Flexible movement: The conveyor is equipped with sturdy wheels for easy movement and cleaning as needed.

➤ Technical Specifications:

Electrical Power: 1.25 kW – 380/220 VAC – 50 Hz

Length: 300 cm

Width: 80 cm

Height: 300 cm

Machine Number: 006

Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High industrial quality according to European standards. Durable structure and highly efficient performance.

➤ Why choose this conveyor? 100% hygienic design compliant with global food standards.

Easy maintenance and cleaning for increased efficiency and reduced downtime.

Smooth and reliable movement ensures uninterrupted production flow.

European manufacturing quality ensures long-lasting performance and a long service life.

fryer server

Smart and organized feeding of Cheetos or pellet chips into the fryer to ensure smooth flow and optimal production! The fryer feeder is an essential part of the production line. It collects the product in a special tank and feeds it into the fryer regularly and efficiently thanks to the smart shaker system.

➤ How it works:

1. ✅ Main collection tank: Holds up to 100 kg of chips (Cheetos or pellet), ensuring adequate storage for continuous production.

2. ✅ Professional shaker: Equipped with a Turkish-made shaker of high-quality Belgian quality, it operates with a variable-speed system to precisely adjust the flow rate of the material into the fryer tub.

3. ✅ Regular feeding: The shaker ensures continuous and even feeding of the material into the fryer without interruption or clumping.

4. ✅ Healthy food manufacturing: All parts in contact with the product are made of food-grade 304 stainless steel to ensure hygiene and easy maintenance.

➤ Technical Specifications:

Electrical Power: 3.75 kW – 380/220 VAC – 50 Hz

Length: 130 cm

Width: 100 cm

Height: 160 cm

Machine Number: 007

Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High industrial quality according to European standards. Robust construction and highly efficient performance.

➤ Why choose this fryer feeder? Full control of the chip flow speed into the fryer to increase frying efficiency.

High-quality manufacturing combines strength, durability, and Belgian precision.

Hygienic, food-industry-friendly design ensures the highest hygiene standards.

Automatic feeding system reduces waste and enhances production continuity.

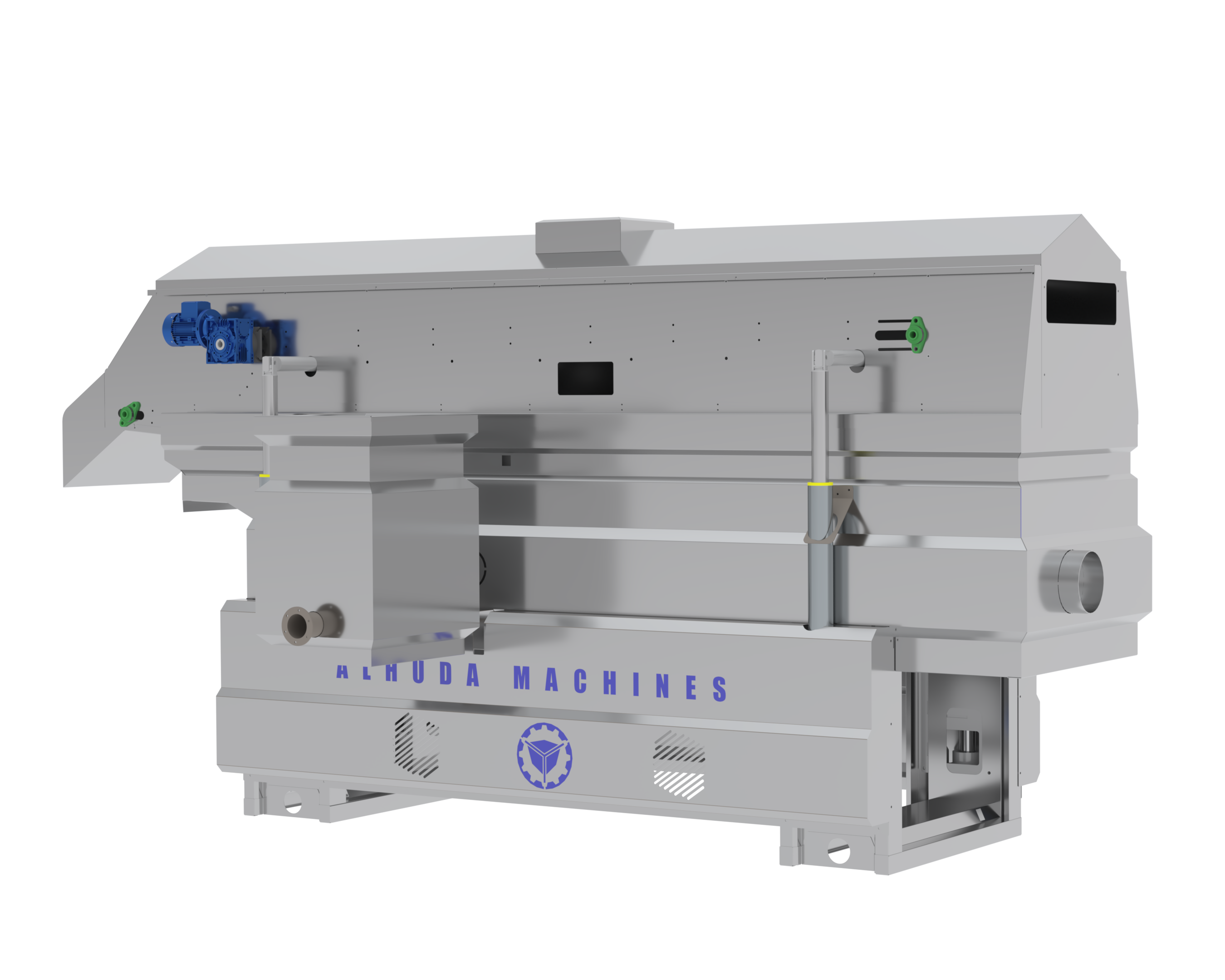

Continuous fryer

🌀 Advanced engineering for professionally frying chips – superior performance, high efficiency, and an ideal design for 24/7 operation! This fryer is specially designed to ensure continuous production and high-quality chips, with careful attention to the smallest details of the thermal process, guaranteeing you a finished product that is cooked and delicious according to global industrial standards. Important Note: This model is inspired by advanced Italian frying systems and is equipped with an upper (ship) lift and lower system operated by an oil pressure hydraulic system, providing safe and easy control during maintenance and cleaning, with maximum user protection.

➤ Detailed Operation Mechanism:

1. ✅ Advanced Engineering Frying Tub: The fryer is a tub filled with oil, through which chips are carefully immersed and stirred in the oil to achieve perfect cooking.

2. ✅ Fast and Precise Frying Time: Chips are cooked in just 15 seconds, ensuring crispiness and complete cooking without excessive oil absorption.

3. ✅ Integrated conveyor with a vibrator: After frying, the chips are gradually lifted onto a mesh conveyor with a built-in vibrator system to remove excess oil as the first stage of product filtration.

4. ✅ Hydraulic vessel lifting system: Equipped with a system for raising and lowering the upper part (the vessel) using oil pressure hydraulics, completely safe and easy to use, facilitating periodic maintenance and cleaning.

5. ✅ Internal fire chamber: Equipped with an advanced internal heating chamber for direct oil heating. The burner operates on either diesel or natural gas, depending on the customer's preference. The fire chamber is fully insulated with a 10 cm thick fiberglass layer on all sides to ensure high thermal safety.

6. ✅ Optimal thermal insulation: Maintains a stable oil temperature, significantly reducing diesel or gas consumption, and providing a safe environment for workers surrounding the fryer.

➤ Technical Specifications:

Electrical Power: 10.5 kW – 380/220 VAC – 50 Hz

Length: 550 cm

Width: 120 cm

Height: 220 cm

Machine Number: 008 Model: THV-2025 SH-Z Country of Manufacture: Made in Turkey

➤ Fryer Features:

✔️ Durable design designed for 24-hour continuous operation.

✔️ Smart heating system and complete thermal insulation for energy savings and increased safety.

✔️ Quickly cooks chips in just 15 seconds with the best color and crispiness.

✔️ Safe and easy hydraulic lift system for easy and safe operation.

✔️ Extremely easy cleaning and daily maintenance thanks to the smart fire chamber design.

✔️ Made entirely of 304 food-grade stainless steel to ensure the highest standards of hygiene and quality.

💡 The smart solution for producing perfect chips with world-class quality – an industrial fryer carefully thought out to meet the needs of modern factories!

Two oil tanks

Smart solutions for frying oil management – highly efficient automatic storage and feeding, ensuring constant temperature even in the harshest winter conditions! These tanks are specially designed to support continuous and regular industrial fryer operation, using a dual system for feeding new oil to the fryer and storing used oil in a healthy and safe manner.

➤ Detailed working mechanism:

1. ✅ Large capacity: Each tank has a capacity of 320 liters, ensuring sufficient oil for long, uninterrupted production periods.

2. ✅ Double jacket design: The space between the two walls is filled with water. This maintains the oil temperature and prevents it from freezing, especially during harsh winters.

3. ✅ Efficient heating system: Each tank is equipped with two powerful electric heaters to ensure constant oil temperature.

4. ✅ Dual pumps: The first pump is dedicated to automatically replenishing the fryer with new oil when needed. The second pump transfers the used oil to the filtration unit for refining or storage.

5. ✅ High-quality industrial engineering: Tank body thickness: 3 mm. Strong 3 mm thick bases and 3-inch pipes ensure durability and long service life.

6. Tank Functions: 7. Tank 1: Automatically feeds the fryer with clean, fresh oil. Tank 2: Stores used oil after frying in an organized and safe manner.

➤ Technical Specifications:

Electrical Power: 3.75 kW – 380/220 VAC – 50 Hz

Length: 250 cm

Width: 120 cm

Height: 150 cm

Machine Number: 009

Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High-quality manufacturing according to European standards. Durable construction and highly efficient performance.

➤ Oil Tank Features: Continuously feeds the fryer with fresh oil without manual intervention.

Smart thermal design prevents oil freezing and saves energy.

Powerful industrial pumps ensure easy and fast transfer between tanks, fryer, or filter.

High-quality 304 food-grade stainless steel construction ensures cleanliness and easy maintenance.

Full support for the production line and reduces downtime due to oil shortages or coldness.

Oil drying vibrator

🌀Effective drying, perfect consistency, and consistent performance – the smart solution for removing excess oil after frying! The oil drying shaker is one of the most important post-frying stages in the potato chips production line. It removes excess oil from fried chips using high-frequency vibration, ensuring a crispy, oil-free product while preserving the quality and appearance of the chips.

⚙️ Smart working mechanism:

1️⃣ High vibration for effective drying

✔️ Operates with a high-frequency vibration system that efficiently removes residual oil from the surface of the chips.

✔️ Prevents fried potato chips from sticking together.

✔️ Reduces the oil content of the final product and preserves its natural taste.

2️⃣ 4-stage progressive motion system

✔️ A four-stage progressive conveyor works with carefully coordinated movement to filter the oil gradually and evenly.

✔️ Provides smooth oil drainage without damaging the chips.

3️⃣ Hygienic and Safe Design

✔️ Made entirely of food-grade 304 stainless steel to ensure product safety and easy cleaning.

✔️ Corrosion and moisture resistance, making it suitable for continuous use in an industrial environment.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 4.5 kW

✅ Dimensions: Length: 300 cm, Width: 100 cm, Height: 140 cm

✅ Machine Number: 010

✅ Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High industrial quality according to European standards. Durable construction and highly efficient performance.

💡 Why Choose the THV-2025 SH-Z Oil Drying Shaker?

✔️ Effectively drains excess oil to ensure the quality of the final product.

✔️ Prevents chips from sticking together and breaking during transportation and processing.

✔️ A progressive motion system ensures stable and balanced performance.

✔️ A hygienic and durable design that fits advanced production lines.

✔️ Controlled power consumption and high industrial performance.

🔹 The ideal choice for purifying chips from excess oil and maintaining quality in every piece!

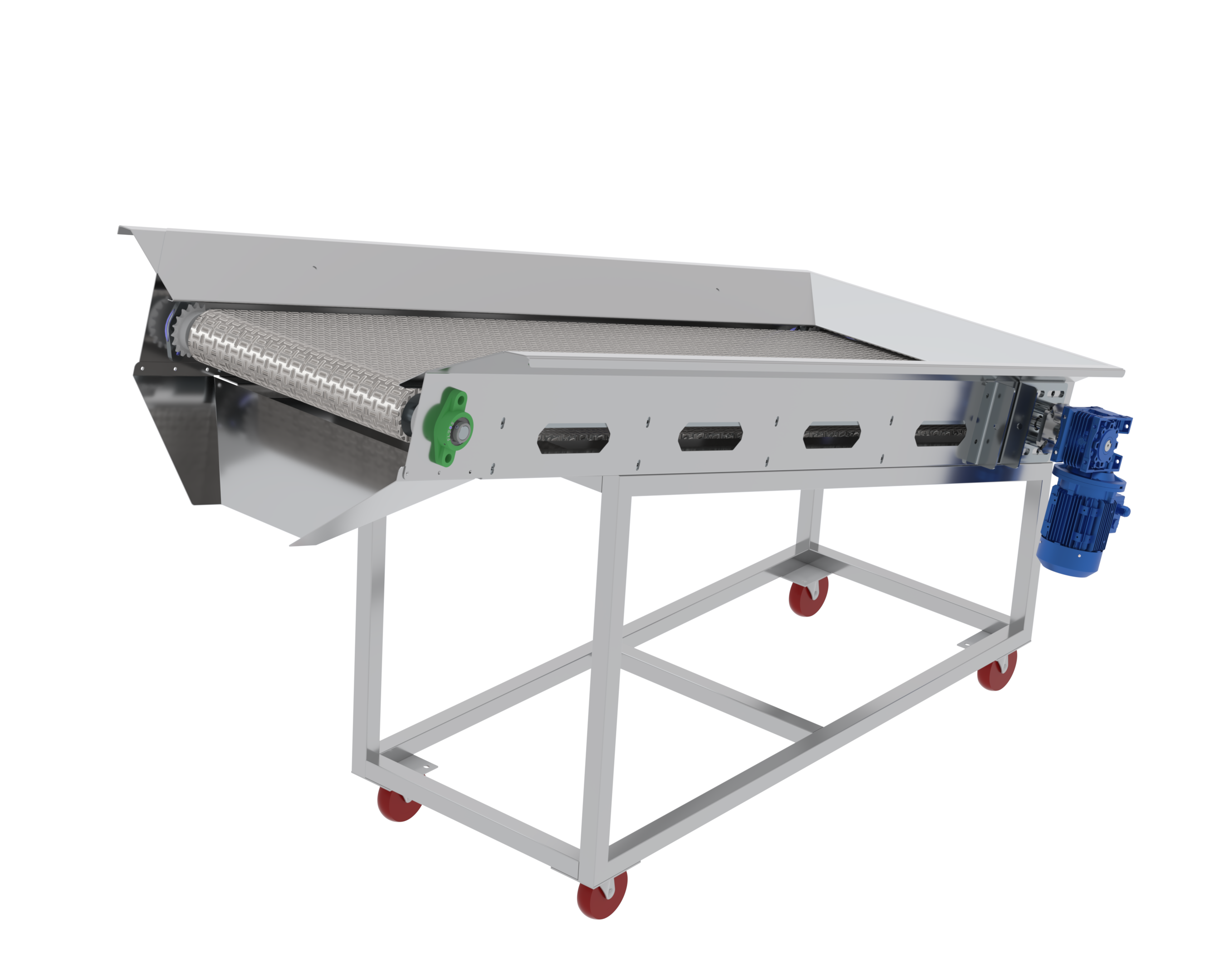

Chips cooling process

Balanced Cooling and Perfect Seasoning Preparation – Smooth Transfer and Consistent Quality Before the Flavoring Stage! This grid line serves as a crucial transition between frying and seasoning, gently cooling the chips and providing a "resting" period before they enter the seasoning tank. This system ensures the chips maintain their ideal texture and prepare them for optimal flavor reception.

⚙️ Efficient Working Mechanism:

1️⃣ Chip Cooling and De-Heating

✔️ The line cools the chips after they leave the shaker and before entering the seasoning tank.

✔️ This gives the chips sufficient time to lose excess heat, promoting better flavor bonding.

✔️ Maintains a crisp texture and prevents chip deformation.

2️⃣ Smooth Transfer to the Seasoning

✔️ Streamlined design ensures chips move easily into the seasoning tank.

✔️ Prevents stacking or damage during transportation and maintains an even product distribution.

3️⃣ Hygienic and Strong Construction Material

✔️ The body is made entirely of food-grade 304 stainless steel, resistant to rust and moisture.

✔️ Easy to clean and maintain daily.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 1.25 kW

✅ Dimensions:

Length: 300 cm

Width: 70 cm

Height: 100 cm

✅ Machine Number: 011

✅ Model: THV-2025 PV-Z

✅ Country of Origin: Turkey – High-quality manufacturing according to European standards. Durable structure and highly efficient performance.

💡 Why choose this mesh line?

✔️ Ideally prepares chips for the seasoning stage.

✔️ Reduces product temperature without the need for complex cooling systems.

✔️ Simple and efficient design made from food-grade materials.

✔️ Stable performance and easy cleaning and operation.

🔹 The perfect choice for ensuring consistent flavor and quality of chips before seasoning!

Flavoring device

The final touch for a distinctive taste – precise and perfect distribution of flavor powder on every chip! The flavoring device is an essential and pivotal part of the potato chips production line. It is used to evenly distribute the flavor powder onto the chips after they have been cooled, ensuring a balanced taste and attractive appearance in every pack.

➤ Detailed working mechanism:

1. ✅ Powder mixing tank: Equipped with an internal mixing device to continuously stir the flavor powder and prevent clumping. This ensures the flavor is always ready for immediate feeding.

2. ✅ Horizontal feeding screw: Transfers the flavor from the tank to the spray unit in a gradual and regular manner. This helps precisely control the amount of flavor fed to the vibrator.

3. ✅ Flow control inverter: Equipped with an electronic inverter that allows the amount of flavor supplied to be adjusted according to the product type and desired density.

4. ✅ Precise distribution and calibration: The system is designed to achieve the best coating of chips without waste or irregularities.

5. ✅ Professional food design: All parts are made of food-grade 304 stainless steel, ensuring the highest levels of hygiene and ease of maintenance.

➤ Technical Specifications:

Electrical power: 2.25 kW – 380/220 VAC – 50 Hz

Length: 140 cm

Width: 80 cm

Height: 160 cm

Machine number: 012

Model: THV-2025 SH-Z

✅ Country of origin: Turkey – High industrial quality according to European standards. Durable construction and highly efficient performance.

➤ Flavoring device features:

Ideal and precise flavor distribution for a consistent taste throughout the product.

Smart industrial design to minimize flavor powder waste.

Easy to adjust and calibrate to suit your desired flavor and type.

Durable and efficient for continuous production lines.

Easy to disassemble and clean to ensure consistent quality and cleanliness.

Flavor coating cylinder

Profesyonel lezzet dağıtım sanatı - yavaş dönüş, mükemmel kaplama ve her cipste tutarlı lezzet kalitesi! Tamburlu baharatlayıcı, patates cipsi üretim hattının son ve kritik aşamasıdır. Patates cipsleri, mükemmel bir lezzet ve profesyonel bir görünüm sağlamak için kendine özgü aromalarıyla eşit ve hassas bir şekilde kaplanır.

➤ Detaylı Mekanizma:

1. ✅ Döner Gıda Tamburu: Ürün hijyeni ve kolay temizlik sağlamak için tamamen gıda sınıfı 304 paslanmaz çelikten üretilmiştir. Patates cipslerini kırmadan optimum lezzet dağılımı sağlamak için yavaş ve ölçülü bir hızda döner.

2. ✅ Elektronik Hız Kontrolü: Patates cipsi türüne ve ürün hassasiyetine göre tamburun dönüş hızını hassas bir şekilde kontrol etmek için modern bir invertör ile donatılmıştır.

3. ✅ Gelişmiş Lezzet Püskürtücü: Yeni, kalibre edilmiş, Amerikan yapımı bir lezzet püskürtücü ile donatılmıştır. Patates cipsleri baharatlayıcı içinde dönerken pürüzsüz ve tutarlı bir lezzet püskürtmesi sağlar.

4. ✅ Topaklanmayı önleyici tasarım: Baharatın içindeki özel çıkıntılar, aromanın topaklanmasını veya yapışmasını önleyerek tüm cipslere eşit dağılım sağlar.

5. ✅ Talaş süresi kontrolü: Talaşların tambur içinde kalma süresi, istenen aroma türüne ve kaplama kalınlığına göre kalibre edilebilir ve ayarlanabilir.

6. ✅ Parçacık atma mekanizması: Baharatlama işlemi sırasında çok küçük taneleri veya istenmeyen kırıntıları atan özel bir sistemle donatılmıştır ve nihai ürünün kalitesini korur.

7. ✅ Kolay taşınabilirlik ve temizlik: Kullanımdan sonra kolay hareket ve temizlik için şık bir krom kapak ve dayanıklı tekerleklerle donatılmıştır.

➤ Teknik Özellikler:

Elektrik Gücü: 3,75 kW – 380/220 VAC – 50 Hz

Uzunluk: 300 cm

Genişlik: 120 cm

Yükseklik: 150 cm

Makine Numarası: 013

Model: THV-2025 SH-Z

✅ Menşei Ülke: Türkiye – Avrupa standartlarına uygun yüksek kaliteli üretim. Dayanıklı yapı ve yüksek verimli performans.

➤ Silindirik Baharatlama Makinesinin Özellikleri:

Her cipste tutarlı bir lezzet ve mükemmel bir doku sağlamak için optimum aroma kapsamı.

Akıllı tasarımı, aroma tozunun silindir içinde topaklanmasını ve yapışmasını önler.

İsrafsız homojen püskürtme için yüksek performanslı aroma püskürtücü. Daha hızlı bakım için son derece kolay kalibrasyon ve temizlik.

Her türlü cips ve çıtır atıştırmalık ürünler için idealdir.

Artık Cheetos, Palet veya Doğal Patates Cipsi üretim hattının her bir parçasının detaylı ve kapsamlı bir açıklamasına sahipsiniz.

Electrical parts and control panels

Schneider breakers

Schneider contactors

Delta control panel

Delta inverters

Gamak motors

Yilmaz gearboxes

Or as per customer request

Basic information

🟧 Cheetos Chips Production Line - Frying System.

🔹 An integrated industrial solution for producing crunchy corn chips, the famous Cheetos. The Cheetos Chips Production Line with Frying System is one of the reliable industrial solutions offered by Al-Huda International Company. This line is used to produce a single type of Cheetos-flavored corn chips, relying entirely on oil frying to achieve the rich taste and famous crunchy texture. Designed according to the highest engineering and food standards, this line features easy-to-operate technology, consistent performance, and high manufacturing quality that ensures continuous production and easy maintenance.

⚙️ Line Components and Operational Stages:

1️⃣ Corn Mixer: Mixes corn flour with water and oil in specific quantities inside a mixer made of food-grade stainless steel to ensure dough consistency and prepare it for extrusion.

2️⃣ Screw Conveyor (Screw Conveyor): Smoothly transports the resulting dough from the mixer to the extruder unit, while maintaining the appropriate temperature and flexibility for processing.

3️⃣ Extruder: The core of the line, it shapes the dough into the desired shape using high pressure and heat. It is equipped with several molds to produce the specified shape. The machine includes: a main motor pressure unit, an automatic feeding unit, and electronic temperature control.

4️⃣ Extruder face cutter: Cuts the extruded grains into the desired length using rotating knives mounted on the extruder head.

5️⃣ Pneumatic conveying system: Directly transports the cut grains to the frying unit using a controlled airflow, ensuring rapid conveying and preventing breakage.

6️⃣ Continuous fryer: The primary frying stage, where the grains are fried in hot oil at 170–180°C for 10 to 15 seconds. The fryer is equipped with: A temperature control system, sprinklers to stir the beans in the oil, an oil residue drainage system, and an insulating cover for safety.

7. De-oiling Shaker: Removes excess oil from the beans after frying using gentle vibration, preserving crispness and reducing fat absorption.

8. Pre-cooling Line: Lowers the product temperature before it moves to the seasoning stage, improving flavor adhesion and preventing clumping.

9. Flavoring Drum: A rotating drum equipped with a flavor powder sprinkler that evenly coats the beans with the selected flavor thanks to its adjustable rotation angle and distribution speed.

📐 General Line Features: Operating System: Fully Automatic Product Type: Cheetos Flavored Corn Chips - One Shape Power Source: Electricity, Diesel, or Gas as Requested Manufacturing Materials: 304 Food-Grade Stainless Steel Average Electrical Power: 60–80 kW Installation Area Required: Approximately 400 m² Full Line Length: 26 meters Width: 3 meters

🎯 Features of the Cheetos Frying Production Line:

✅ Fully Automatic Operation with Smart Control Panel

✅ Easy Maintenance and Cleaning Thanks to the Open Design

✅ Integrated Safety System for All Operational Stages

✅ High-Quality Kernel Production and Consistent Flavor

✅ Economical Energy and Fuel Consumption

✅ Flexibility in Adjusting the Frying and Seasoning Degrees According to Product Type

📌 Made in Turkey - Using German Technology and High-Quality European Materials. Al-Huda - Over 20 Years of Industrial Experience in the Snack Production Line Industry