Integrated production line for corn chips and chocolate-filled corn fingers

🔹 One innovation... Double the production! The ZFLEX line is the smart, integrated solution for producing two different products on a single production line: The THV-2025 ZFLEX compact corn chip production line. This fully integrated production line is specifically designed to manufacture both chocolate-filled corn sticks and puffed corn snacks (regular corn chips) using the same system, making it the ideal choice for manufacturers seeking product diversification on a single, highly efficient production line.

🍫 Chocolate-filled corn sticks

🍟 Puffed corn snacks (regular corn chips)

⚙️ Professional design – High performance This line is designed to offer you maximum production flexibility, with quick product changeovers and the highest international quality standards.

✅ Robust extruder system

✅ Precise internal filling unit

✅ Multiple shaping options (various chip shapes)

✅ Industrial-grade mixers, dryers, and seasoning systems

🎯 Why choose the THV-2025 ZFLEX?

✨ Flexible production of two different products

✨ Reduced operating costs and increased product variety

✨ Compact design saves space

✨ CE-certified and ready for operation

🛠️ Al-Huda – Trust Built on Quality We provide the technology... so you can achieve success.

📍 Made in Turkey – German technology – Genuine warranty

The line consists of the following parts

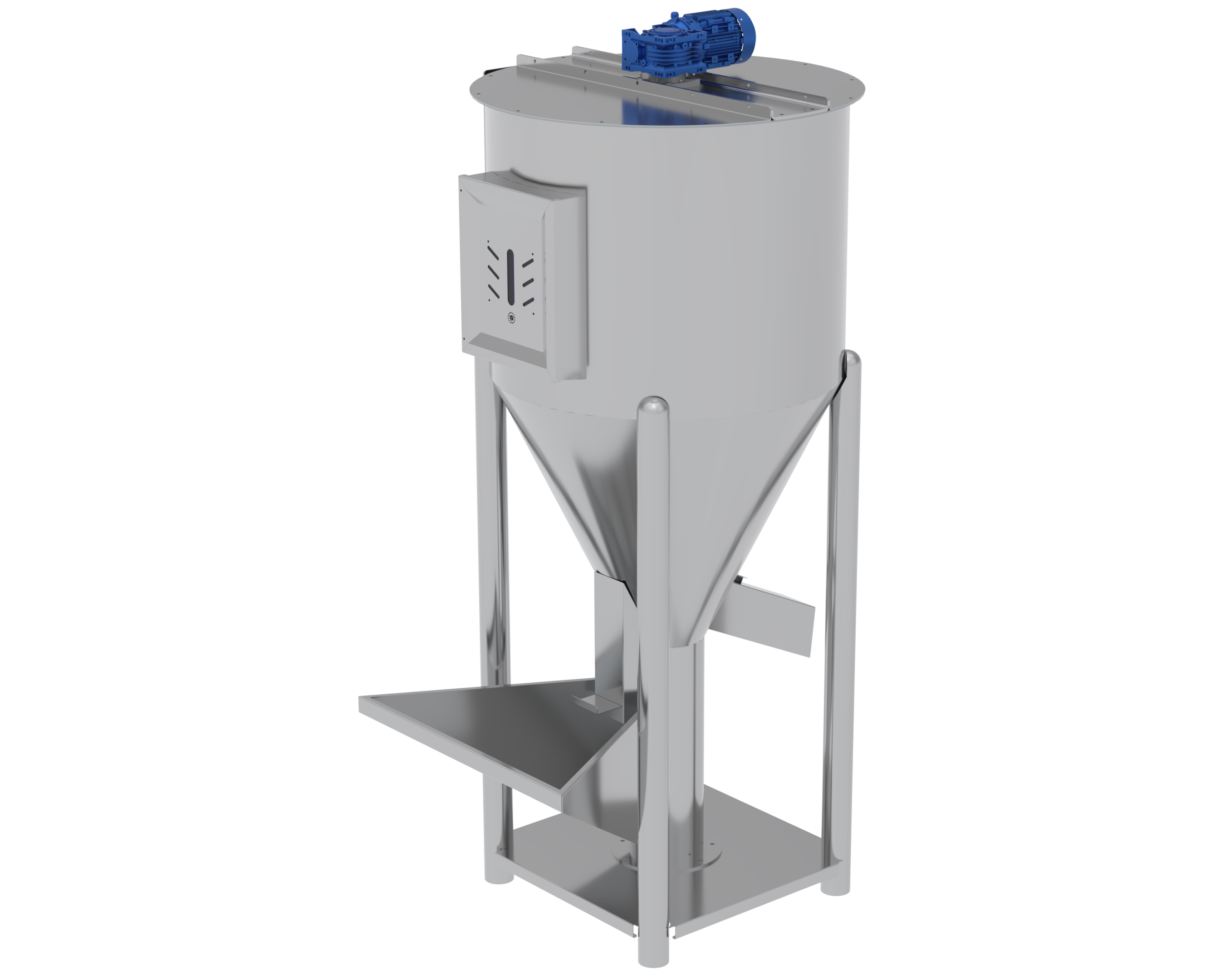

1. Corn mixer

2. Screw conveyor

3. Extruder

4. Air conveyor

5. Corn stick cutter

6. Chocolate tempering machine

7. Product conveyor belt

8. Hot air oven

9. Flavoring solution tanks

10. Flavoring pump

11. Flavoring cylinder

12. Conveyor belt for the packaging machine

13. Packaging and sealing machine

corn mixer

Homogeneous and precise mixing of corn to the highest quality standards. The corn mixer is essential equipment in corn processing before manufacturing, as it achieves perfect homogeneity by mixing the corn with a precise amount of moisture, ensuring even distribution and a professional-quality final product.

Advanced Operating Mechanism

1️⃣ Large capacity and high-quality materials Capacity: 400 kg, allowing for efficient processing of large quantities of corn. Material: Made entirely of 2 mm thick food-grade 304 stainless steel, ensuring rust resistance and maintaining product hygiene.

2️⃣ Powerful motor for optimal mixing performance Main motor: 5 HP Turkish-made motor, ensuring stable and efficient mixing. A homogeneous mixing mechanism guarantees perfect distribution of ingredients within the mixer.

3️⃣ Precise control of corn moisture Equipped with a built-in water tank for controlling the moisture content of the corn to achieve the desired consistency. A water level indicator helps in accurately adjusting the amount during the mixing process.

4️⃣ High safety system for worker protection Equipped with a mechanical safety guard (metal mesh) that prevents the operator's hand from entering the mixer during operation, ensuring a safe working environment.

5️⃣ Smooth discharge and control system Equipped with a calibrated discharge opening for easy product removal without clumping or material loss. Includes a viewing and cleaning port, allowing for monitoring of the mixing process and ensuring the mixer remains clean after each use.

6️⃣ Effective removal of metal impurities The mixer bowl contains a powerful magnet that removes any metal impurities from the corn, ensuring the purity of the final product and preventing unwanted materials from entering subsequent production stages. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Power: 3.75 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 180 cm

Width: 120 cm

Height: 230 cm

✅ Machine Number: 001

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards. Durable construction and high performance.

✔️ 2 mm thick inner lining for corrosion resistance and long-lasting durability.

✔️ Smooth discharge system for easy control of the corn output after mixing.

✔️ High-level mechanical safety features to ensure operator safety during operation.

✔️ Magnet inside the tank to remove any metal impurities that could affect product quality.

✔️ Precise control of corn moisture through a built-in water tank and level indicator.

✔️ Robust and durable design made entirely of food-grade 304 stainless steel for maximum hygiene.

✔️ High-level safety system with a metal mesh guard to prevent accidental contact with moving parts.

✔️ Effective removal of metal impurities using the built-in magnet in the tank.

✔️ Easy emptying and cleaning through designated openings.

✔️ High-performance motor for optimal mixing efficiency and superior product quality.

💡 The ideal solution for ensuring consistent mixing and professional corn preparation with the best quality and operational efficiency!

Spiral conveyor

Precise and efficient automated material conveying for maximum safety and quality

The screw conveyor is a vital piece of equipment in production lines. It automatically feeds materials to the extruder smoothly and efficiently, ensuring a consistent flow, improving production efficiency, and guaranteeing maximum safety and product quality.

Advanced Operating Mechanism

1️⃣ Spacious hopper made of high-quality materials

Capacity: 75 kg, allowing sufficient storage of materials to ensure uninterrupted production.

Material: Made entirely of 2mm thick food-grade 304 stainless steel, providing high corrosion resistance and ensuring product hygiene.

2️⃣ Automatic feeding to the extruder for a consistent flow

The conveyor automatically feeds materials to the extruder, reducing manual intervention and ensuring continuous and efficient operation.

The precise screw design guarantees smooth material transport without clumping or flow interruptions.

3️⃣ Robust safety system for worker protection

Equipped with a safety mesh that prevents accidental contact with the moving parts during operation, providing a safe working environment.

4️⃣ Efficient removal of metal impurities

Features a sophisticated magnetic system that effectively removes any metal impurities present in the materials, maintaining product quality and protecting the machinery from damage.

5️⃣ Easy cleaning and maintenance

Includes a dedicated bottom opening for easy cleaning, facilitating routine maintenance and removal of any residual material from the hopper.

Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel for the highest hygiene and quality standards.

✅ Power: 1.25 kW | 380/220 V | 50 Hz.

✅ Dimensions:

Length: 300 cm

Width: 90 cm

Height: 250 cm

✅ Machine Number: 002

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards.

Robust design and high operational efficiency

✔️ 2 mm thick inner frame for corrosion resistance and long-lasting durability.

✔️ Precise screw design for homogeneous material transport without clumping.

✔️ Easy discharge system via the bottom opening, facilitating maintenance and cleaning.

✔️ High mechanical safety standards to ensure operator safety during operation.

✔️ Effective removal of metal impurities using the integrated magnetic system.

✔️ Automatic feeder for the extruder to ensure a consistent flow and improved production efficiency.

✔️ Durable frame made of food-grade 304 stainless steel for hygiene and quality.

✔️ Integrated safety system with a metal mesh to prevent accidents during operation.

✔️ Efficient removal of metal impurities with the built-in magnetic system.

✔️ Easy maintenance and cleaning thanks to the dedicated bottom opening.

✔️ Energy-efficient design with low power consumption.

💡 The ideal solution for precise and safe material handling, achieving the highest quality and operational efficiency standards!

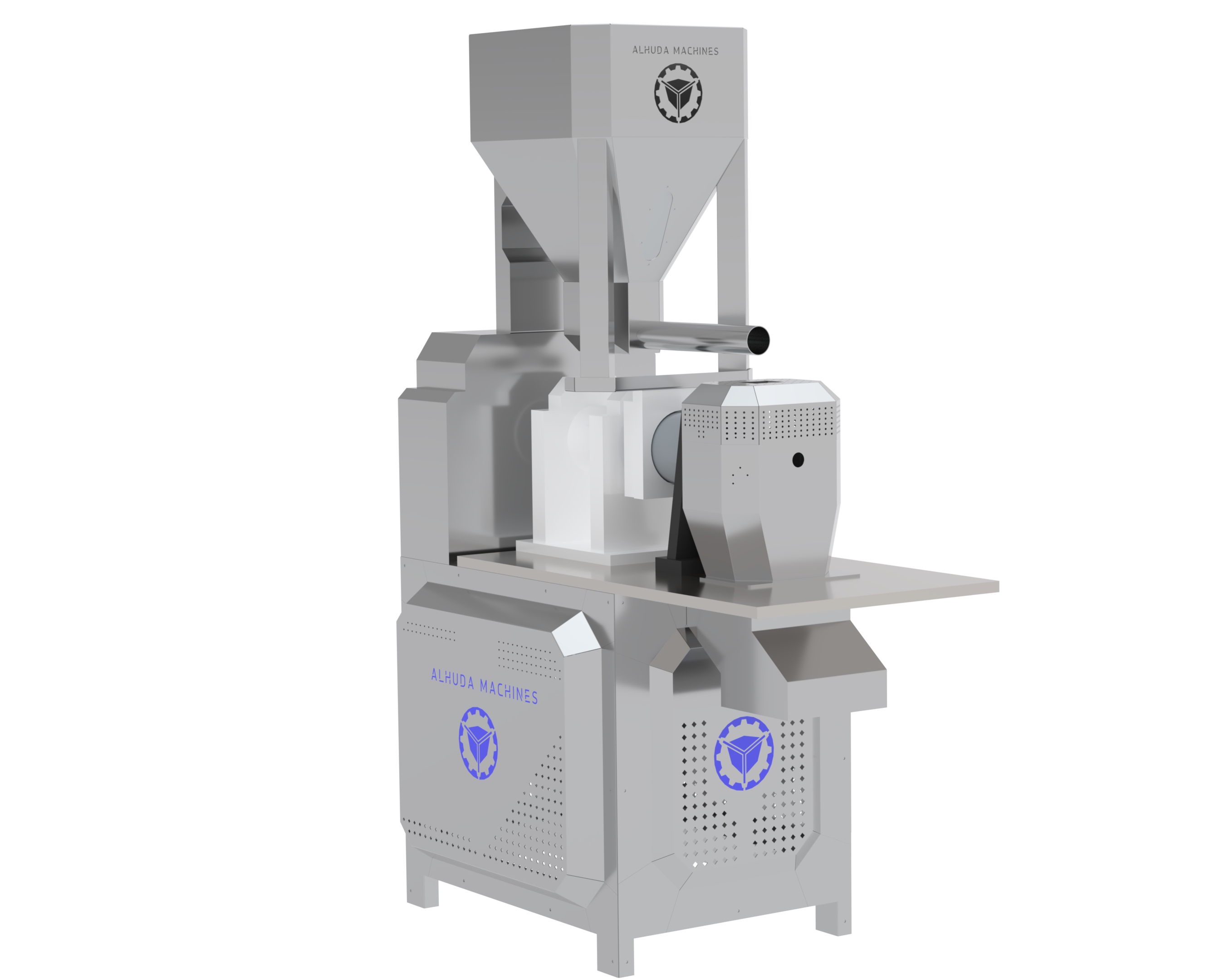

Extruder

Professional performance for producing high-quality puffed snacks. The extruder is essential equipment in the food industry, producing puffed snacks in various shapes using advanced manufacturing technologies. This ensures consistent, high-efficiency production, with precise control over the shape and size of the final product.

Advanced Operating Mechanism

1️⃣ High production capacity and continuous operation: Production capacity ranges from 200 kg/hour to 175 kg/hour depending on the desired snack shape. Designed for continuous 24-hour operation thanks to a heavy-duty gearbox made of premium materials, according to American Extrusion standards.

2️⃣ Durable construction for reliability and longevity: The main frame is made of hot-dip galvanized steel, protected from corrosion and impact by a modern oven coating. Completely insulated with food-grade 304 stainless steel for easy cleaning and compliance with hygiene standards. Approximate weight: 1400 kg, ensuring stability during operation.

3️⃣ Advanced drive system for enhanced reliability: Bearings and bushings are manufactured by SKF (Swedish and Japanese), guaranteeing smooth operation and long lifespan. The screws are made of premium materials and heat-treated using advanced vacuum oven technology, ensuring resistance to high temperatures and pressure during operation. Equipped with a main screw that automatically feeds the extruder screw with material via an inverter, allowing precise control of the feeding process.

4️⃣ Integrated electronic control for operational flexibility: All extruder motors are electronically controlled via 3 inverters, ensuring smooth control of different speeds. Electronically variable speed cutter (inverter) for easy adjustment of pellet length according to production needs. Equipped with a pre-heating system for startup and precise electronic temperature control.

5️⃣ Dual cooling system for stable performance: A water cooling system (closed loop) based on the American Extrusion model ensures high cooling efficiency and minimizes water consumption. An additional air cooling system maintains stable temperatures during continuous operation.

6️⃣ Smart control panel for efficient process monitoring: A standalone main control panel made of food-grade 304 stainless steel, featuring a special ventilation system for hot environments. Equipped with 3 ventilation filters and 3 cooling fans to ensure stable performance in harsh industrial environments. The control panel is sealed to prevent dust ingress, guaranteeing clean and reliable operation.

Includes a classic control panel for full operational control, with a sophisticated software system that automatically detects and alerts users of any malfunctions. Operational data can be automatically stored, and a detailed electrical diagram is provided for easy maintenance and troubleshooting.

Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel for the highest quality and hygiene standards.

✅ Power: 37 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 180 cm

Width: 120 cm

Height: 240 cm

✅ Machine Number: 003

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial equipment, manufactured to European standards. Durable Design and High-Efficiency Performance

✔️ Main frame made of hot-dip galvanized steel for robust performance under harsh operating conditions.

✔️ Automatic feeding system with an electronically controlled auger for consistent material flow.

✔️ 50 HP (37 kW) Italian-made auger drive motor with copper windings for superior durability and stable performance.

✔️ Cast iron main motor housing for enhanced durability and pressure resistance.

✔️ Full electronic speed and length control via advanced inverters.

✔️ Dual cooling system (water + air) to maintain stable temperatures during continuous operation.

✔️ Sealed, smart control panel with dedicated cooling and ventilation for use in hot environments.

✔️ Output capacity up to 200 kg/hour with easy pellet shape control.

✔️ Powerful, high-efficiency motors from reliable, global brands.

✔️ Durable food-grade 304 stainless steel construction for hygiene and easy cleaning.

✔️ Dual cooling system maintains stable performance and prevents overheating.

✔️ Full electronic control via advanced inverters for precise and smooth operation.

✔️ Advanced control panel capable of displaying fault codes and storing operational data.

✔️ Safe and environmentally friendly design with a closed-loop cooling system for water conservation.

💡 The ideal solution for producing high-quality extruded snacks, with maximum efficiency and consistent performance!

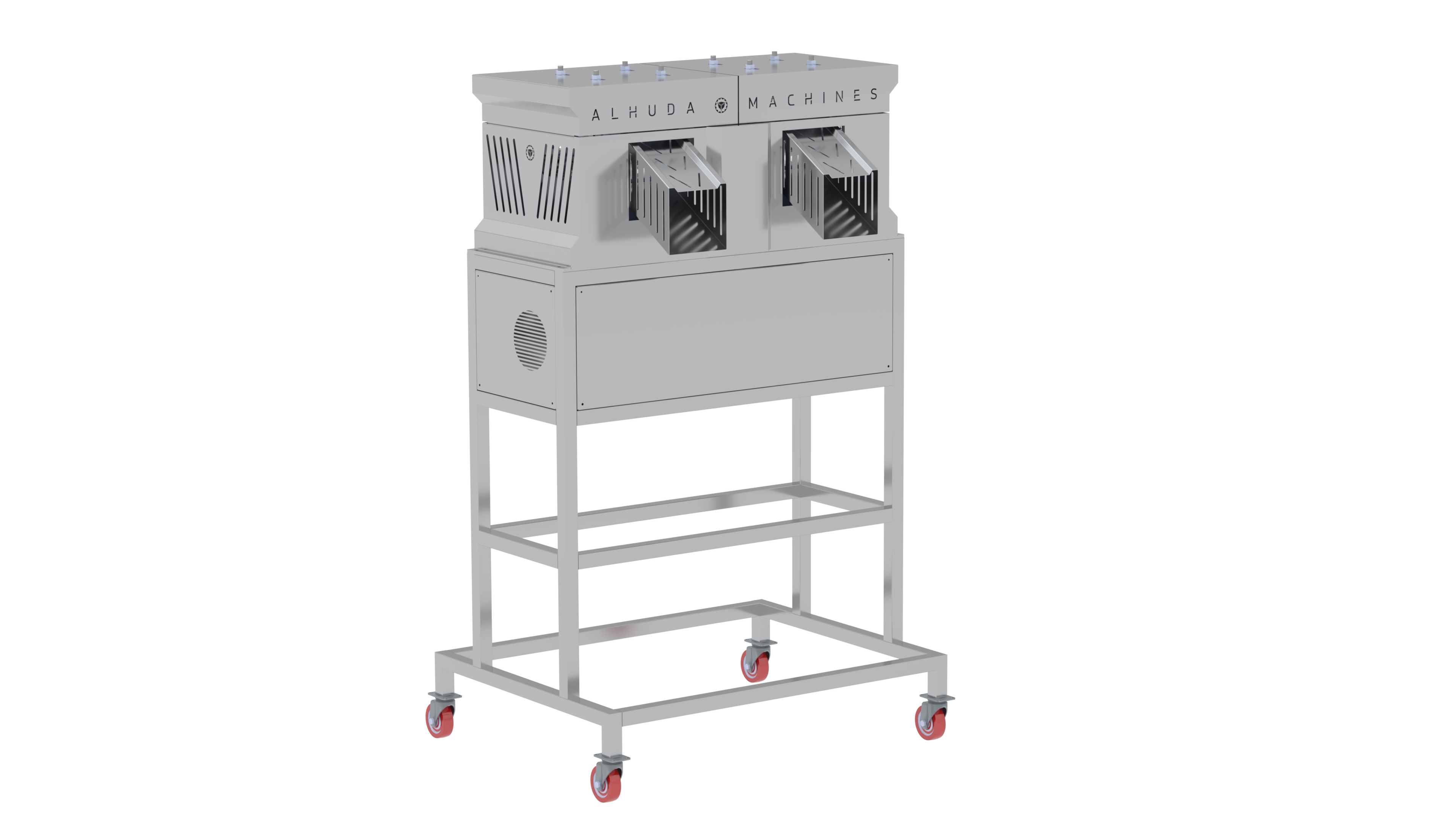

Corn chips cutter

Precise control of chip length – accurate cutting and high-quality design! This cutter is used in the post-forming stage to cut corn chips (puffs) to the desired length with precision and ease. It features electronic length adjustment via an inverter, making it ideal for meeting various production requirements.

⚙️ Operating Mechanism:

1️⃣ Precise and Adjustable Cutting

✔️ The cutter speed is electronically controlled by an inverter.

✔️ Chip length can be set precisely from 2 cm to 15 cm.

2️⃣ Hygienic and Durable Design

✔️ The entire outer frame is made of food-grade 304 stainless steel, ensuring product safety and easy cleaning.

📏 Technical Specifications:

✅ Machine Type: Corn Chip Cutter

✅ Cutting Mechanism: Motor with inverter for length adjustment

✅ Adjustable Length: 2 cm to 15 cm

✅ Material: Food-grade 304 stainless steel

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 1.25 kW

✅ Dimensions:

✔️ Length: 120 cm

✔️ Width: 90 cm

✔️ Height: 150 cm

✅ Machine Number: 004

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey

💡 Why choose this cutter for your production line?

✔️ It offers flexible and precise control of chip length.

✔️ It is made of hygienic materials suitable for the food industry.

✔️ It is easy to operate and clean, and suitable for continuous operation in production lines.

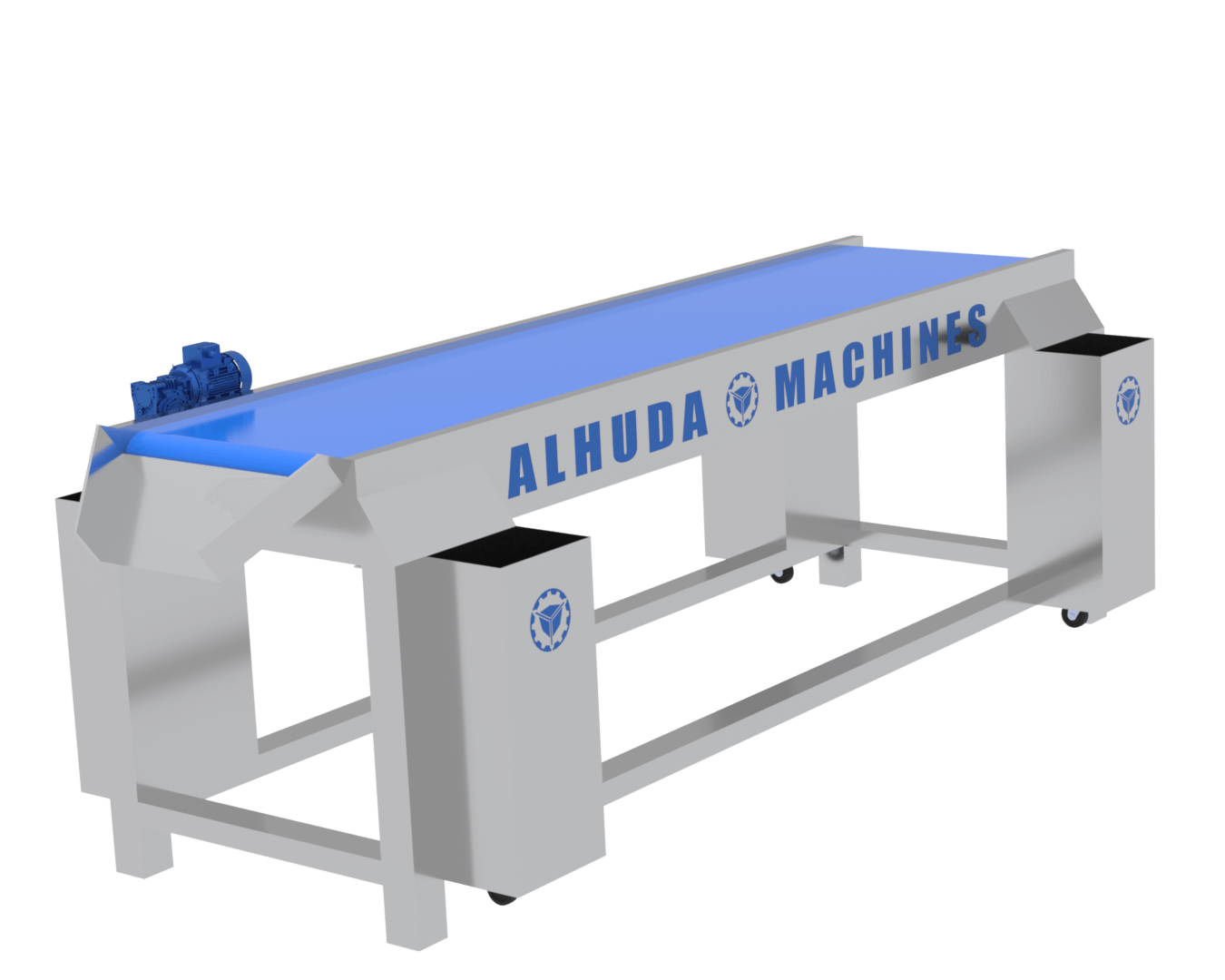

Chips conveyor belt

Professional product conveying between production stages. The product conveyor belt is essential equipment in production lines, ensuring smooth and safe material transfer from the extruder to the oven. Its robust design and advanced features guarantee the highest standards of hygiene and efficiency. Advanced operating mechanism:

1️⃣ Durable frame for strength and longevity: Made entirely of food-grade 304 stainless steel, ensuring high resistance to rust and easy cleaning. Equipped with sturdy casters for easy movement and periodic cleaning within the production line.

2️⃣ High-quality food-grade conveyor belt: The conveyor belt is made of PVC or food-grade plastic to ensure hygienic and safe product transport. The non-stick surface prevents material from adhering during transport, maintaining product quality.

3️⃣ Integrated cleaning system: Features dedicated cleaning openings for easy maintenance and to prevent residue buildup. Includes automatic cleaning brushes that continuously remove any debris or residue during operation.

4️⃣ Energy-efficient and economical operation: Low power consumption (1.25 kW) ensures economical operation without energy waste. Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel for hygiene and durability.

✅ Power: 1.25 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 300 cm

Width: 80 cm

Height: 200 cm

✅ Machine Number: 005

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured to European standards. Features of the Product Conveyor Belt

✔️ Robust design made entirely of food-grade 304 stainless steel to ensure the highest hygiene standards.

✔️ Smooth and safe transport of materials from the extruder to the oven, without any product damage.

✔️ Conveyor belt made of PVC or food-grade plastic for hygienic transport.

✔️ Integrated automatic cleaning system with cleaning brushes and access panels for maintenance.

✔️ Wheels for easy movement and cleaning, providing operational flexibility.

✔️ Low energy consumption with high operational efficiency.

💡 The ideal solution for safe and efficient product transport in food production lines!

Kong chocolate cooking tank

Two integrated solutions for preparing melted chocolate with the highest quality and thermal efficiency! First – The Chocolate Melting Unit: A professional, double-jacketed unit for smoothly melting and refining chocolate, equipped with a mixer, an internal circulation pump, and grinding balls to improve texture and quality.

⚙️ Technical Specifications – Melting Unit:

✅ Capacity: 600 kg

✅ Design: Double-walled (double jacket) for circulating hot water

✅ Heating: Electronically controlled electric heating elements

✅ Chocolate circulation: An internal pump circulates the chocolate from the bottom to the top for optimal refining

✅ Refining: Metal balls inside the tank

✅ Cooling: Double jacket with a pump to circulate water for efficient cooling

✅ Wall thickness: Inner wall: 8 mm; Outer wall: 4 mm; Tank bottom: 15 mm

✅ Includes a control panel Second – The Chocolate Holding Tank (Warmer): A dedicated tank for maintaining the fluidity of the chocolate and preventing it from solidifying, thanks to a double-jacketed heating system and precise electronic temperature control.

⚙️ Technical Specifications – Melting Tank:

✅ Capacity: 600 kg

✅ Design: Double jacket for hot water heating

✅ Heating: Electric heaters with electronic control

✅ Hot water circulation: Integrated pump

✅ Wall thickness: Inner wall: 4 mm; Outer wall: 4 mm; Base: 6 mm

✅ Material: Food-grade 304 stainless steel

✅ Equipped with an electrical control panel

✅ Voltage: 380/220 VAC – 50 Hz

✅ Power: 10.5 kW

✅ Dimensions:

✔️ Length: 180 cm

✔️ Width: 120 cm

✔️ Height: 170 cm

✅ Machine ID: 008

✅ Model: THV-2025PV-Z

✅ Country of origin: Turkey

💡 Why is this system ideal?

✔️ Maintains the quality and smoothness of the chocolate throughout the process.

✔️ Easy to clean and maintain thanks to its hygienic design.

✔️ Precisely controls the temperature to prevent clumping or burning.

✔️ Seamless integration of the melting tank and cooking unit ensures smooth and stable production flow.

Product conveyor belt

Professional product conveying between production stages. The product conveyor belt is essential equipment in production lines, ensuring smooth and safe material transfer from the extruder to the oven. Its robust design and advanced features guarantee the highest standards of hygiene and efficiency.

Advanced Operating Mechanism

1️⃣ Durable and robust frame: Made entirely of food-grade 304 stainless steel, ensuring high resistance to corrosion and easy cleaning. Equipped with sturdy casters for easy movement and periodic cleaning within the production line.

2️⃣ High-quality food-grade conveyor belt: The conveyor belt is made of PVC or food-grade plastic to ensure hygienic and safe product transport. The non-stick surface prevents material from adhering during transport, maintaining product quality.

3️⃣ Integrated cleaning system: Features dedicated cleaning openings for easy maintenance and to prevent residue buildup. Includes automatic cleaning brushes that continuously remove any debris or residue during operation.

4️⃣ Energy-efficient operation: Low power consumption (1.25 kW) ensures economical operation without energy waste.

Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel for hygiene and durability.

✅ Power: 1.25 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 300 cm

Width: 80 cm

Height: 200 cm

✅ Machine Number: 007

✅ Model: THV-2025PV-Z

✅ Country of Origin: Türkiye – High-quality industrial product, manufactured to European standards. Features of the Product Conveyor Belt

✔️ Robust design made entirely of food-grade 304 stainless steel to ensure the highest hygiene standards.

✔️ Smooth and safe transport of materials from the extruder to the oven, without any product damage.

✔️ Conveyor belt made of PVC or food-grade plastic for hygienic transport.

✔️ Integrated automatic cleaning system with cleaning brushes and access panels for maintenance.

✔️ Wheels for easy movement and cleaning, providing operational flexibility.

✔️ Low energy consumption with high operational efficiency.

💡 The ideal solution for safe and efficient product transport in food production lines!

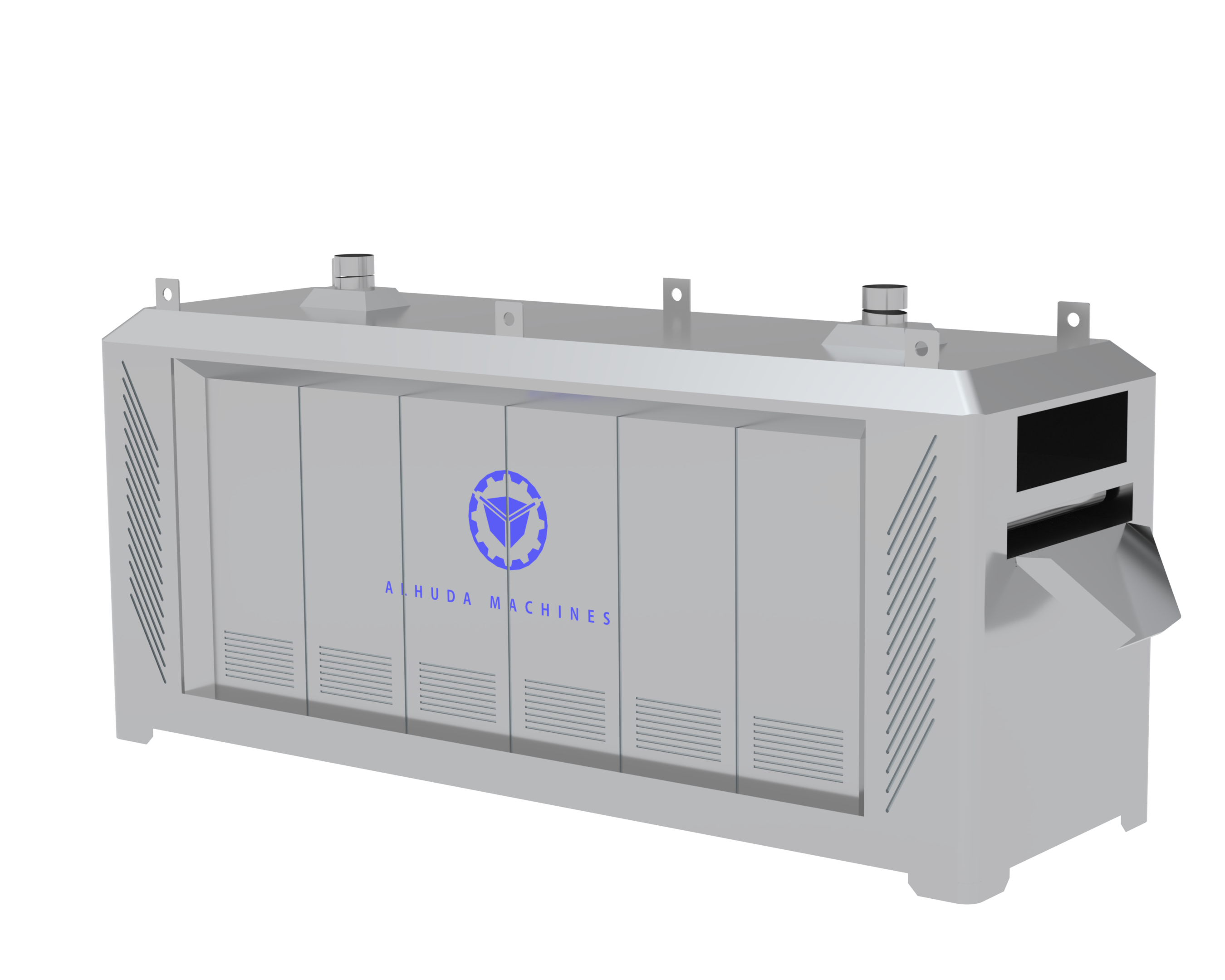

hot air grill oven

Professional roasting and drying using hot air technology. The hot air roasting oven is one of the most advanced technologies used for roasting and drying potato chips. It relies on a uniform heat distribution that ensures an optimal final product quality, with precise control of humidity and temperature to adjust texture and flavor to your specifications.

Advanced Operating Mechanism

1️⃣ High productivity with precise temperature control. Production capacity of up to 400 kg per hour, making it ideal for large-scale production lines. Temperature can be adjusted up to 300°C, depending on the product type and processing requirements. Control of the final product moisture content from 0% to 5% to guarantee the desired texture.

2️⃣ Efficient and energy-saving heating system. Operates on diesel or natural gas (LPG), depending on customer preference, ensuring economical and efficient operation. Features a removable and easily replaceable heating chamber made of 304 stainless steel, capable of withstanding temperatures up to 800°C. The main burner is either Baltur or Riello (Italian, model 2025), ensuring high operational efficiency.

3️⃣ Durable construction and excellent thermal insulation. Made entirely of food-grade 304 stainless steel for high corrosion resistance and easy cleaning. The oven is fully insulated with 15 cm of fiberglass on all sides to maintain internal temperature and reduce energy consumption.

4️⃣ Advanced product conveyor system with automatic cleaning. The 100 cm wide conveyor belt, made of food-grade 304 stainless steel, ensures even roasting of the product. Equipped with an automatic conveyor belt cleaning mechanism, ensuring product cleanliness and efficient operation. The oven features an LS inverter for precise control of the conveyor belt speed.

5️⃣ Professional air circulation for even baking: Powerful fans circulate hot air, ensuring optimal heat distribution from top and bottom, with recirculation from the sides. 3 HP hot air circulation fan motor (Italian or Turkish – high quality). 3 HP air extraction and recirculation fan motor (Italian or Turkish – high quality).

6️⃣ Advanced control system: Separate control panel made of food-grade 304 stainless steel, easily removable for maintenance and transport. Modern touchscreen control panel with a smart fault detection system that displays error messages to quickly identify and resolve issues.

All electrical components are from Schneider (France) and LS (Korea) for high reliability. The main gearbox is Italian, and the motors are either Italian or Turkish, both of excellent quality. The speed of the hot air circulation and extraction fans is electronically controlled via inverters.

Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel for the highest hygiene and quality standards.

✅ Electrical Power: 10.5 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 650 cm

Width: 150 cm

Height: 220 cm

✅ Machine Number: 008

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured to European standards. Features of the Hot Air Roasting Oven

✔️ High productivity of up to 400 kg/hour with precise temperature and humidity control.

✔️ Durable design and excellent thermal insulation to maintain optimal internal temperature and minimize energy consumption.

✔️ Removable and easily accessible heating chamber for convenient maintenance.

✔️ Advanced air circulation system for even roasting from all sides.

✔️ Food-grade 304 stainless steel conveyor belt with automatic cleaning system.

✔️ Smart touch screen control panel with automatic fault detection system.

✔️ Powerful, European-quality motors and fans for reliable, continuous operation.

💡 The ideal solution for producing high-quality, delicious, and perfectly textured roasted snacks!

Flavor cooking tanks

Precise flavor preparation with indirect heating technology. The flavor cooking tanks are designed to ensure the preparation of food flavors at the highest quality standards. They utilize an indirect heating system (double jacket) to provide even heating without affecting the flavor composition, resulting in an optimal flavor distribution in the final product.

Advanced Operating Mechanism

1️⃣ Professional design of the indirect heating system: The tank is constructed using double-jacket technology, allowing the water surrounding the tank to be heated instead of directly heating the flavor itself. This ensures the flavor retains its optimal quality without burning or altering its composition. With a heating capacity of up to approximately 200 liters, it is ideal for large production lines. A water level indicator monitors the hot water level in the tank, ensuring continuous and reliable operation.

2️⃣ Durable and robust construction for industrial environments: Made entirely of food-grade 304 stainless steel, guaranteeing high resistance to corrosion and easy cleaning and sterilization. The base frame is made of galvanized steel and covered with stainless steel for added durability and protection. The tank and pump are mounted on a single frame for easy installation and maintenance. Heavy-duty casters facilitate movement and cleaning, allowing for easy transport within production lines.

3️⃣ Precise temperature control system: Equipped with a digital temperature gauge for continuous monitoring of the hot water temperature inside the tank, ensuring precise control of the heating process. A uniform heat distribution system prevents hot spots within the flavor, guaranteeing a consistent final product.

Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality. ✅ Power: 3.75 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 230 cm

Width: 130 cm

Height: 170 cm

✅ Machine Number: 009

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards. Features of the Flavor Cooking Tank:

✔️ Double-jacketed design for indirect heating, preserving flavor quality.

✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning.

✔️ Equipped with a water level indicator and a temperature gauge for precise temperature control.

✔️ Robust frame made of hot-dip galvanized steel for durability and longevity.

✔️ Equipped with wheels for easy movement and cleaning, making it suitable for various production lines.

✔️ Large capacity of up to 250 liters, making it ideal for large-scale industrial production.

💡 The perfect solution for preparing flavors with the highest precision and quality!

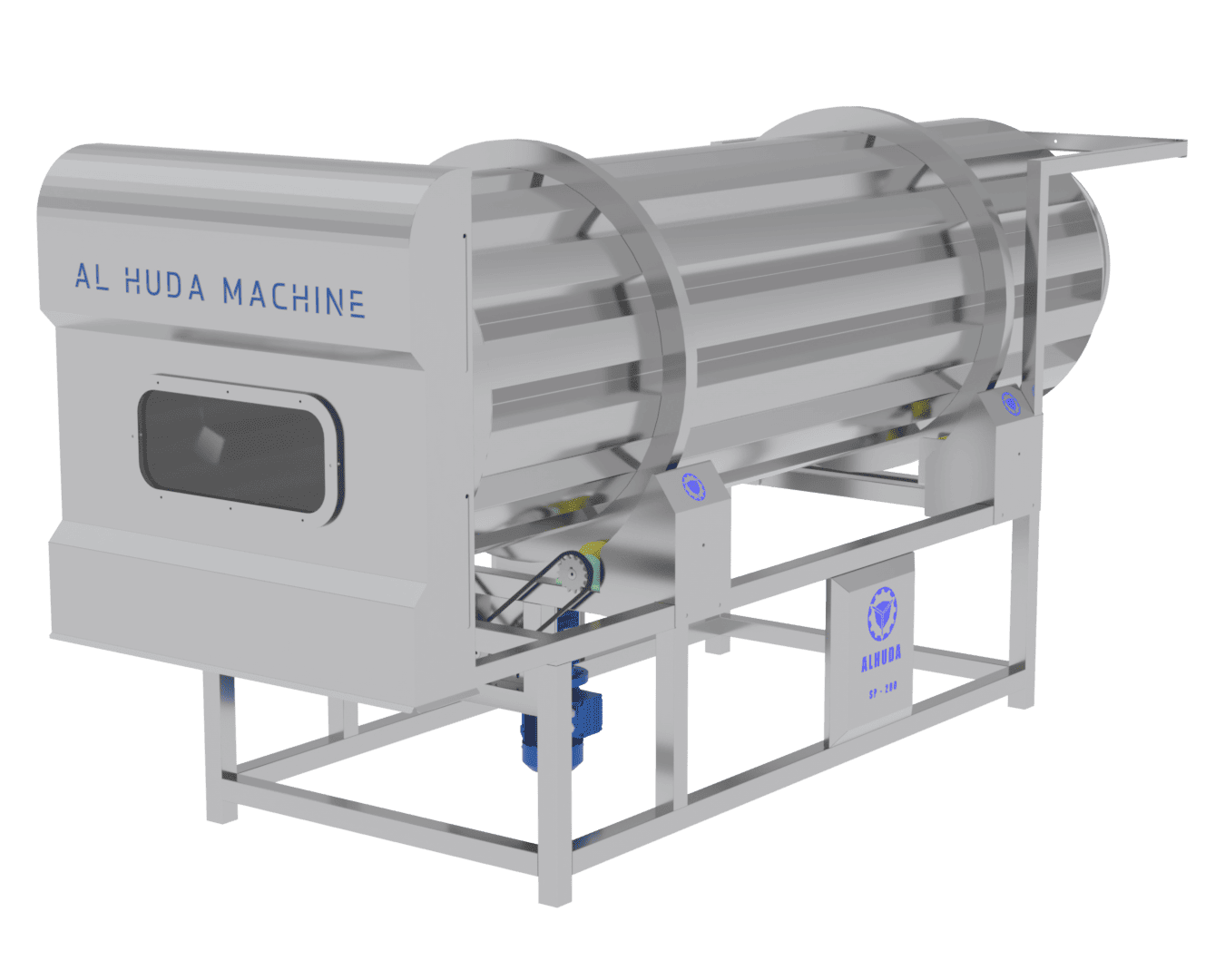

Flavor coating cylinder

Uniform flavoring for optimal taste and quality: The flavoring unit is a crucial stage in chip production, ensuring even flavor distribution across all chips. This is achieved through a sophisticated flavor spray system and a slow, balanced rotation mechanism that prevents clumping or settling.

Advanced Operating Mechanism

1️⃣ Precise Electronic Control: The rotation speed of the flavoring unit is electronically controlled via an inverter, allowing for precise adjustment of the chip's transit time within the drum, depending on the product type. The unit is also calibrated to adjust the flavoring level as needed, guaranteeing consistent results batch after batch.

2️⃣ Advanced Flavor Spray System for Perfect Coverage: Equipped with a high-precision, adjustable (US-made) flavor spray nozzle, this system ensures a uniform and precise flavor distribution without waste. The baffles inside the drum are designed to prevent flavor clumping, contributing to consistent flavoring of each chip.

3️⃣ Impurity Removal and Enhanced Product Quality: Features an automatic impurity and small chip removal mechanism, ensuring the final product has the ideal size and texture. The chips rotate slowly during the flavoring process, allowing for complete coverage without breakage.

4️⃣ Durable and Easy-to-Clean Design: Made entirely of food-grade 304 stainless steel for the highest hygiene and safety standards. A chrome-plated cover at the product outlet protects the product and prevents spillage. Heavy-duty casters facilitate easy movement and cleaning, making it ideal for industrial environments.

Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel for the highest hygiene and quality standards.

✅ Power: 3.75 kW | 380/220 volts | 50 Hz

✅ Dimensions:

Length: 300 cm

Width: 120 cm

Height: 150 cm

✅ Machine number: 010

✅ Model: THV-2025PV-Z

✅ Country of origin: Turkey – High-quality industrial product, manufactured according to European standards. Features:

✔️ Electronic inverter control system for precise adjustment of the drum rotation speed.

✔️ Advanced American-made flavor spray nozzle for optimal flavor distribution.

✔️ Internal design with perforated plates that prevent flavor clumping and ensures even seasoning.

✔️ Automatic ejection mechanism for impurities and unwanted small particles.

✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning.

✔️ Equipped with sturdy casters for easy movement and cleaning.

💡 The ideal solution for consistent seasoning and ensuring high quality of your chip products!

Flavor pump

Advanced technology for precise and efficient flavor dispensing. The flavor pump is a key component of any chip production line, precisely dispensing and distributing flavor through an innovative alternating suction and pumping system. This ensures optimal flavor usage and consistent flavor coverage on the final product.

Advanced Operating Mechanism

1️⃣ Alternating Suction and Pumping Technology (Advanced American System): The pump utilizes an alternating suction and pumping system, a modern American technology that precisely controls flavor flow and minimizes waste, resulting in highly efficient and economical flavor usage.

2️⃣ Powerful Motor and Durable Construction: Equipped with a robust geared motor and a high-quality European-made aluminum pump, ensuring reliable performance and consistent pumping speed. The pump body is made of sturdy European-grade aluminum, making it corrosion-resistant and capable of continuous operation.

3️⃣ Precise Electronic Flavor Control: The amount of flavor dispensed is electronically controlled via an inverter, allowing for precise adjustment of the pumping rate according to the product type and production requirements.

4️⃣ Practical and Easy-to-Maintain Design: The pump is mounted on a food-grade 304 stainless steel base, providing stability and ease of movement and cleaning. A flexible rubber coupling connects the motor and pump, facilitating quick maintenance and disassembly. A food-grade Spanish-made silicone hose ensures safe flavor transfer without compromising quality. The unit features sturdy casters for easy movement and cleaning, making it ideal for industrial production lines. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Power: 1.125 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 80 cm

Width: 60 cm

Height: 80 cm

✅ Machine Number: 011

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards.

✔️ Advanced American technology for precise flavor dispensing and minimal waste.

✔️ Powerful geared motor and European-made aluminum pump for consistent performance.

✔️ Precise electronic control system for flavor dispensing volume via inverter.

✔️ Practical design with a food-grade 304 stainless steel base and casters.

✔️ Easy maintenance thanks to a rubber coupling for quick assembly and disassembly.

✔️ Equipped with a Spanish-made food-grade silicone hose for safe flavor transfer.

💡 The ideal solution for efficient flavor dispensing and ensuring consistent flavor for every chip!

Basic information

🌟 A Compact Production Line for Corn Chips and Chocolate-Filled Corn Sticks – From Al Huda Company

The corn chip production line is one of the most profitable and widely used industrial lines in the global market, thanks to the high demand for snack foods across all age groups. With technological advancements and innovation, Al Huda Company has introduced this unique compact line that combines the production of two types of products:

1. Traditional Corn Chips (Puffed/Flaked Snacks):

The most popular and in-demand product in the market.

Known for its crispiness and delicious taste, it is a staple snack found in all stores and supermarkets.

2. Chocolate-Filled Corn Sticks:

An innovative product that combines delicious crispy corn sticks with a rich chocolate filling.

It increases product variety, enhances market value, and gives the factory a strong competitive advantage.

⚙️ Technical Specifications of the Line:

Line length: 20 meters.

Required operating area: 300 square meters for efficient and comfortable operation.

Power consumption: 80 kW.

Fuel consumption (diesel or gas): Only 5 liters per hour.

✅ Features of the Line:

A compact and smart line: It allows the production of two types of snacks (traditional corn chips + chocolate-filled corn sticks) on the same line.

A profitable investment: It combines the most popular and widely consumed products, ensuring continuous sales and high profits.

Flexible operation: Easy transition between producing regular corn chips and chocolate-filled corn sticks.

European quality: Utilizes European and German manufacturing technologies to guarantee excellent performance and long-lasting durability. Robust construction: All parts that come into contact with the product are made of high-quality, food-grade stainless steel.

Energy efficiency: Low electricity and fuel consumption, despite high production capacity.

Practical and well-designed: The production line can operate in a relatively small space, starting from just 300 square meters.

📊 Why is this production line profitable?

Its products are in high demand daily in all markets (corn chips are among the best-selling snacks).

Producing two different types of snacks diversifies your product range and increases sales and distribution opportunities.

The products can be easily marketed through grocery stores, supermarkets, and distributors.

The growing demand for snacks makes this a long-term and sustainable business venture.

💡 In summary:

Al-Huda's compact corn chips and chocolate-filled corn stick production line is a guaranteed, successful investment that combines efficiency, quality, and profitability. This single line allows you to enter two different markets with popular and successful products, while maintaining low energy consumption and requiring minimal operating space.